-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Enco 12x36 Lathe Rebuild (Picture Heavy!)

- Thread starter macardoso

- Start date

- Joined

- Mar 26, 2018

- Messages

- 2,724

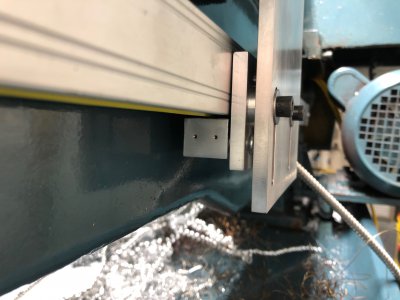

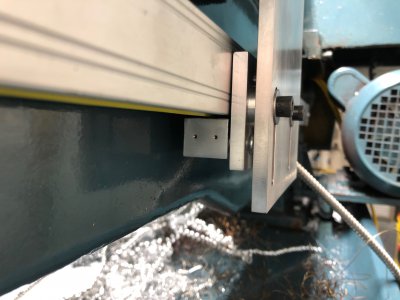

For the carriage DRO, I did a lot of hand designing of the parts as I went. This plate became the mount between the scale read head and the plate on the carriage.

This larger plate had the slots cut on the CNC. It connects the carriage to the scale.

The 30 thou relief on the back avoided a ridge in the casting.

The carriage scale attached. I screwed up some measurements which forced me to mount some stuff upside down and shim it, however the install turned out perfectly fine! I could go correct it, but I don't think it is necessary.

With this scale mounted I figured out my issue with machining longer parts. The carriage handwheel accumulates about 15 thou of error (extra travel) per rev (0.7") or about 0.021" error per inch. On a 10 inch part, this would put the tool out of position by almost a quarter inch! Not good! The DRO will solve that problem for me and had a lot of great features like a tool table, and a radius cutting function.

I'm very happy with this product, but the install was a tremendous amount of work.

This larger plate had the slots cut on the CNC. It connects the carriage to the scale.

The 30 thou relief on the back avoided a ridge in the casting.

The carriage scale attached. I screwed up some measurements which forced me to mount some stuff upside down and shim it, however the install turned out perfectly fine! I could go correct it, but I don't think it is necessary.

With this scale mounted I figured out my issue with machining longer parts. The carriage handwheel accumulates about 15 thou of error (extra travel) per rev (0.7") or about 0.021" error per inch. On a 10 inch part, this would put the tool out of position by almost a quarter inch! Not good! The DRO will solve that problem for me and had a lot of great features like a tool table, and a radius cutting function.

I'm very happy with this product, but the install was a tremendous amount of work.

- Joined

- Feb 1, 2016

- Messages

- 67

Macardoso

Nice work that's far more then I did with my Enco 110-2034 lathe. I am interested in the specs on your electric drive motor. One of your first posts gave me that info. The guy I bought mine from had to replace the motor because of the lathe being dropped and I don't have anything showing what it came with.

Thanks

Jim

Nice work that's far more then I did with my Enco 110-2034 lathe.

Thanks

Jim

Last edited:

- Joined

- Mar 26, 2018

- Messages

- 2,724

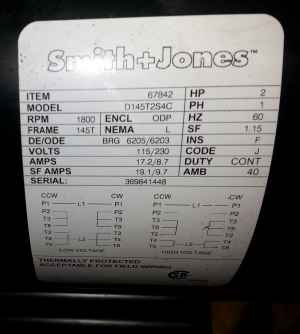

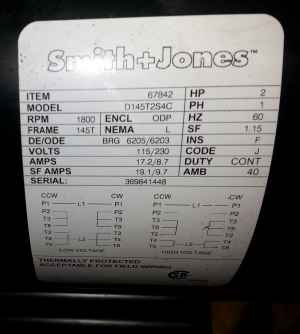

It is a standard 220V single phase reversible (4 wire) motor. I used a pair of 4 pole interlocked contactors to handle the reversal.

It is mounted on a cast iron bracket bolted to the lathe bed. The motor sits on a plate. The plate is hinged to the bracket to create variable center distance to the counter shaft above.

If I had to buy a new motor, I'd buy a 3 phase motor and VFD. I do get surface finish issues from the single phase.

It is mounted on a cast iron bracket bolted to the lathe bed. The motor sits on a plate. The plate is hinged to the bracket to create variable center distance to the counter shaft above.

If I had to buy a new motor, I'd buy a 3 phase motor and VFD. I do get surface finish issues from the single phase.

- Joined

- Feb 1, 2016

- Messages

- 67

Macardoso

Well they were close when the got the replacement motor. Its a Smith+Jones 67842 2hp 1 ph 1800 rpm dual capacitor Nema 145. So my rpms will be a bit faster then the chart but acceptable. Not sure what the 2 hp will do but okay.

The motor hasn't been a problem but the motor shaft and pulley were not aligned causing me to re-bore and make a bushing to get it running true. But now its the motor belt that's introducing a shake into the machine. So I'll replace that too. Only other major problem was the feed shaft was in a bind with the worm gear and for that I had to drop the apron and by trial and error get the worm mount lined up. Now you can get the carriage moving and push it down the ways.

It seems like a good machine and will work for me but its a world of difference from the Lablond, gisholt, monarch, and axelson lathes I ran years ago.

Jim

Well they were close when the got the replacement motor. Its a Smith+Jones 67842 2hp 1 ph 1800 rpm dual capacitor Nema 145. So my rpms will be a bit faster then the chart but acceptable. Not sure what the 2 hp will do but okay.

The motor hasn't been a problem but the motor shaft and pulley were not aligned causing me to re-bore and make a bushing to get it running true. But now its the motor belt that's introducing a shake into the machine. So I'll replace that too. Only other major problem was the feed shaft was in a bind with the worm gear and for that I had to drop the apron and by trial and error get the worm mount lined up. Now you can get the carriage moving and push it down the ways.

It seems like a good machine and will work for me but its a world of difference from the Lablond, gisholt, monarch, and axelson lathes I ran years ago.

Jim

- Joined

- Mar 26, 2018

- Messages

- 2,724

Sounds like you have a bit of work to fix her up but she should run well!

I can only compare to the bigger 14” class lathes we had at school (and I NEVER took a hard cut), but I’m very pleased with this lathe. I can do some small work and bigger stuff when needed. Been using it a lot on the steam engine I am building and I trust myself within a couple of tenths on it.

I can only compare to the bigger 14” class lathes we had at school (and I NEVER took a hard cut), but I’m very pleased with this lathe. I can do some small work and bigger stuff when needed. Been using it a lot on the steam engine I am building and I trust myself within a couple of tenths on it.