- Joined

- Jun 29, 2014

- Messages

- 4,059

UPDATE:

Leveled the glass bed twice today using the method defined by Creality. Pretty simple. I aim to try and get the nozzle to just grab the paper. Did a quick test print and basically got the same results, but slightly better as previously posted.

When I loaded up Cura, it flashed a notice that there was an update. After ignoring it initially, I figured it wouldn't hurt to update.

Once updated, I ran a test print:

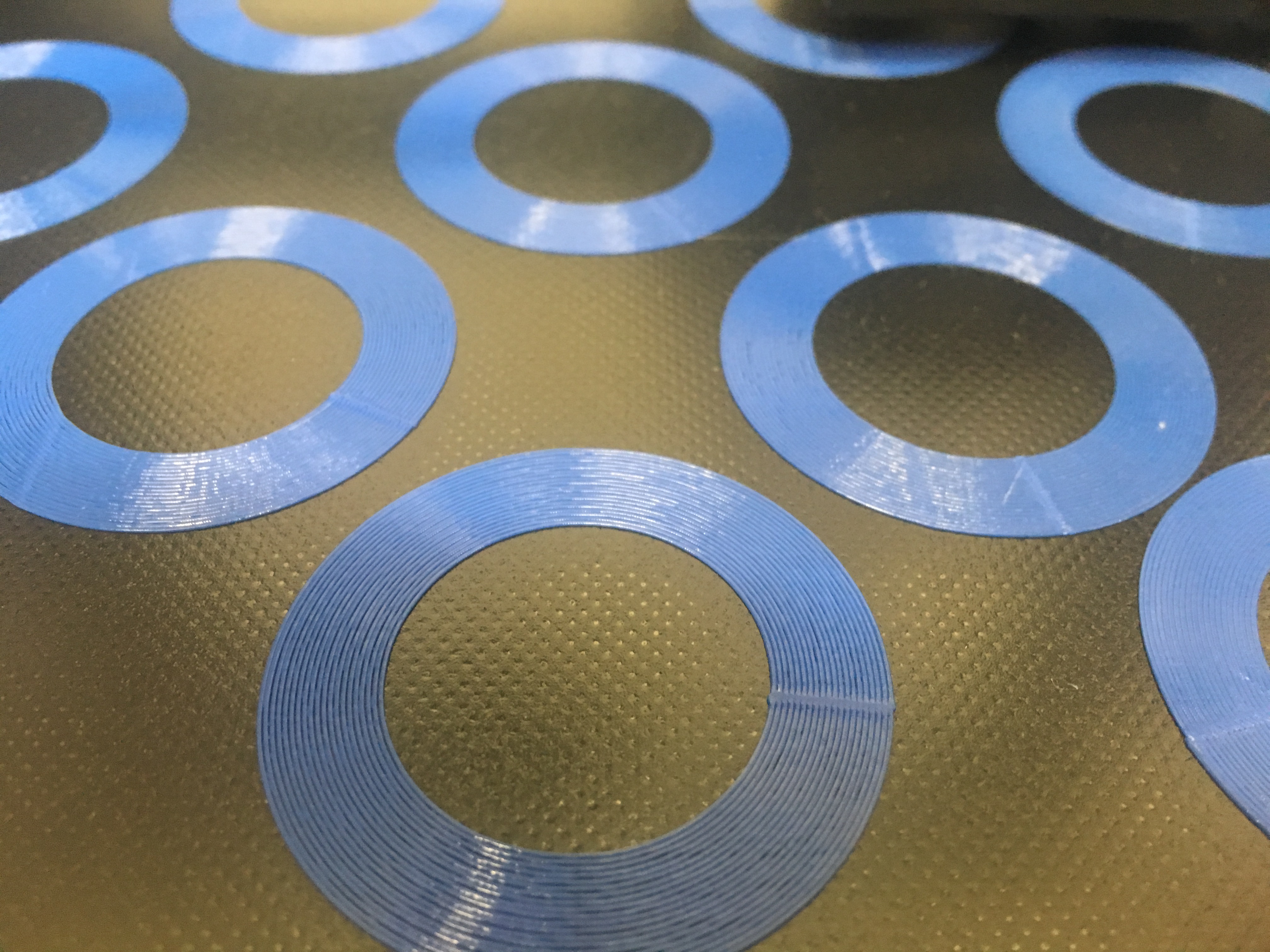

Leveling seemed to help with the print looking evenly squished. However, you can see that there is still a "stitch" across the raft. The stitch occurs in different positions of the clock around the raft.

Conclusion. Paying attention to the leveling helps. Also, it appears that updating Cura (and resetting print configurations in the process) helped bring things back to "normal".

However, the stitching really bothers me and as I watched the X and Y axes, I noticed that the belt on the X was skipping as it went over the stitch. I'll tighten things up tomorrow - but I'm skeptical if that will help. I can't see how a skip could happen every time in the same place and then randomize on each raft like that.

Leveled the glass bed twice today using the method defined by Creality. Pretty simple. I aim to try and get the nozzle to just grab the paper. Did a quick test print and basically got the same results, but slightly better as previously posted.

When I loaded up Cura, it flashed a notice that there was an update. After ignoring it initially, I figured it wouldn't hurt to update.

Once updated, I ran a test print:

Leveling seemed to help with the print looking evenly squished. However, you can see that there is still a "stitch" across the raft. The stitch occurs in different positions of the clock around the raft.

Conclusion. Paying attention to the leveling helps. Also, it appears that updating Cura (and resetting print configurations in the process) helped bring things back to "normal".

However, the stitching really bothers me and as I watched the X and Y axes, I noticed that the belt on the X was skipping as it went over the stitch. I'll tighten things up tomorrow - but I'm skeptical if that will help. I can't see how a skip could happen every time in the same place and then randomize on each raft like that.