- Joined

- Dec 13, 2013

- Messages

- 112

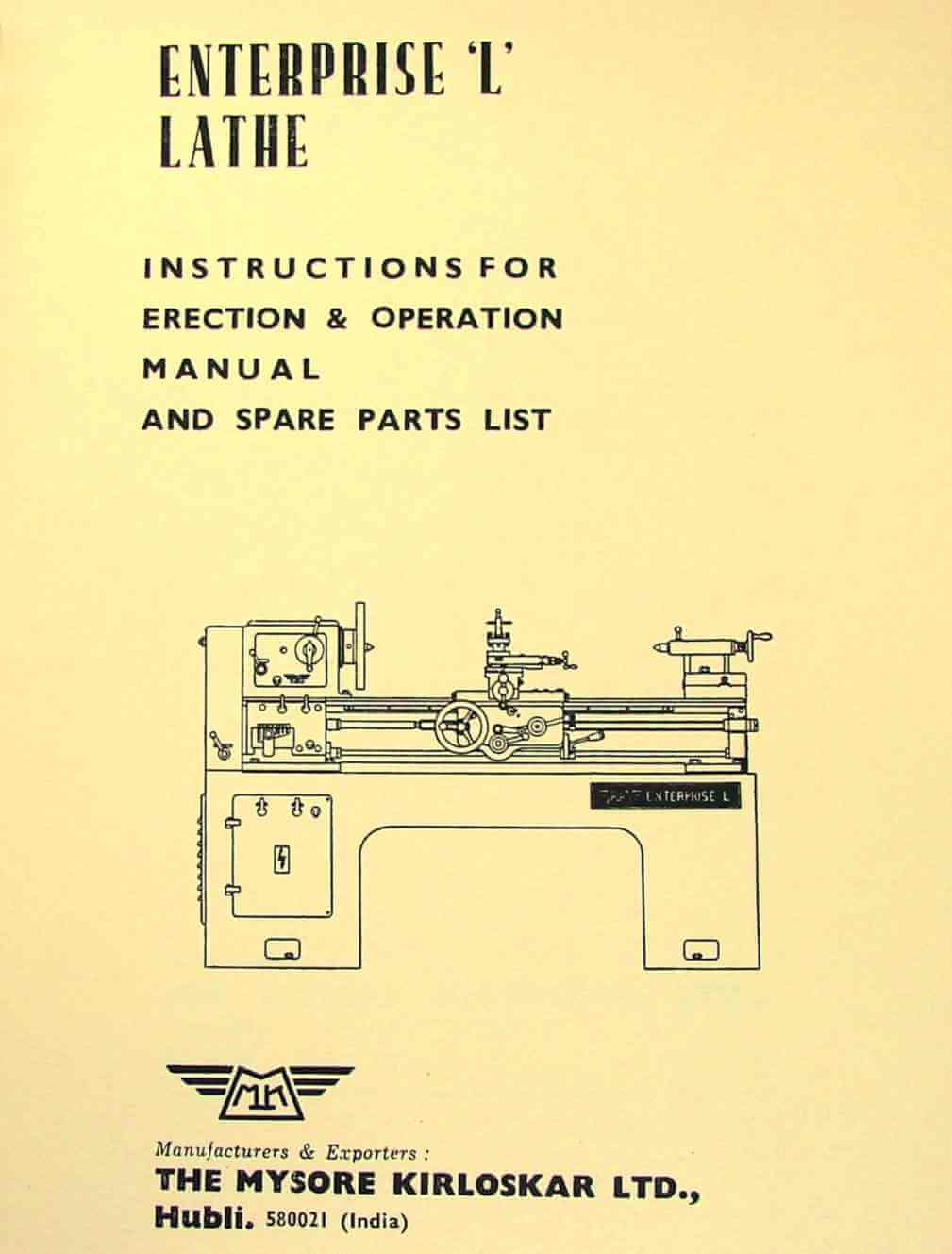

I am a total noob as you will be able to tell soon enough, I just dragged home an Enterprise EL-2 lathe. I am looking for an instruction manual. I have searched far and wide for one with no avail. I thought I would try all avenues before posting. I just heard back from a company in India that can replace nearly any part I need but has no manuals. I would be more than happy to buy one, I am not asking for free.

As a second option if anyone has experience with this lathe and can tell me what the knobs, dials and levers are for and how they work that would be great as well. I would prefer not to shove lever "B" forward before putting dial "A" in the upside down position and taking out all my gears in the process. I have/am disassembling most of it to clean and inspect it, while doing so I am also trying to see what lever is doing what to what, it helps a bit but not enough. If this is a "if no pics posted then it didn't happen" forum I will be happy to post pics ASAP. TIA. JK

As a second option if anyone has experience with this lathe and can tell me what the knobs, dials and levers are for and how they work that would be great as well. I would prefer not to shove lever "B" forward before putting dial "A" in the upside down position and taking out all my gears in the process. I have/am disassembling most of it to clean and inspect it, while doing so I am also trying to see what lever is doing what to what, it helps a bit but not enough. If this is a "if no pics posted then it didn't happen" forum I will be happy to post pics ASAP. TIA. JK