- Joined

- Mar 28, 2013

- Messages

- 13

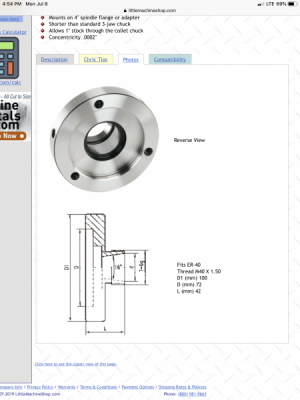

Just purchased this lathe and seeing if anyone has modified a faceplate to work with a through collet chuck similar to the one Little Machine Shop carries (part# 5452). PM has extra faceplates but LMS was concerned that an adapter would need to be machined to fit the 72 mm registration diameter to keep it accurate to the spindle. If anyone has suggestions or a different route they’d take I’d appreciate it as this a first for me. I like the thought of running stock through the headstock vs using a taper mount system but what do I know!

Thanks Skeeter

Thanks Skeeter