- Joined

- Dec 20, 2021

- Messages

- 867

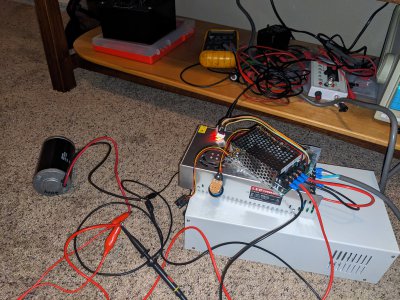

Hmmm,It is a Emerson Astec DS450-3-002. I saw that when poking around today, but think it might be a little 'overkill' and a a little 'oversized'

Instead I ordered this: https://www.amazon.com/dp/B096VL68B1?psc=1&ref=ppx_yo2ov_dt_b_product_details

I had a similar one show up in a kit to make a power supply, and it seems to be good enough. More importantly, it has a much smaller footprint

DS450-3-002 PDF

Part #: DS450-3-002. Description: Distributed Power Bulk Front-End. File Size: 673.81 Kbytes. Manufacturer: Artesyn Technologies.

pdf1.alldatasheet.com

I'm guessing you probably just need to pull pin B6 to B4 to get it to light up (Maybe B6 to logic ground, if it's already high). Shouldn't be too hard to make a spade that would plug into the +12V and +12V Return lines.