- Joined

- Aug 19, 2017

- Messages

- 126

Hey guys, Been slacking of late on posting. Got a strange one , did know where to locate it.

Tell me if I'm fueling the train down the wrong track.

I'll try to be concise.

Kids 2001 Ford Escape 3.0 L Had a noise we thought might be tranny, we parked it for a while and needed to get it going andf ran it over to the Local Tranny shop. They looked at it and figured out it was an idler bearing for a belt. All done

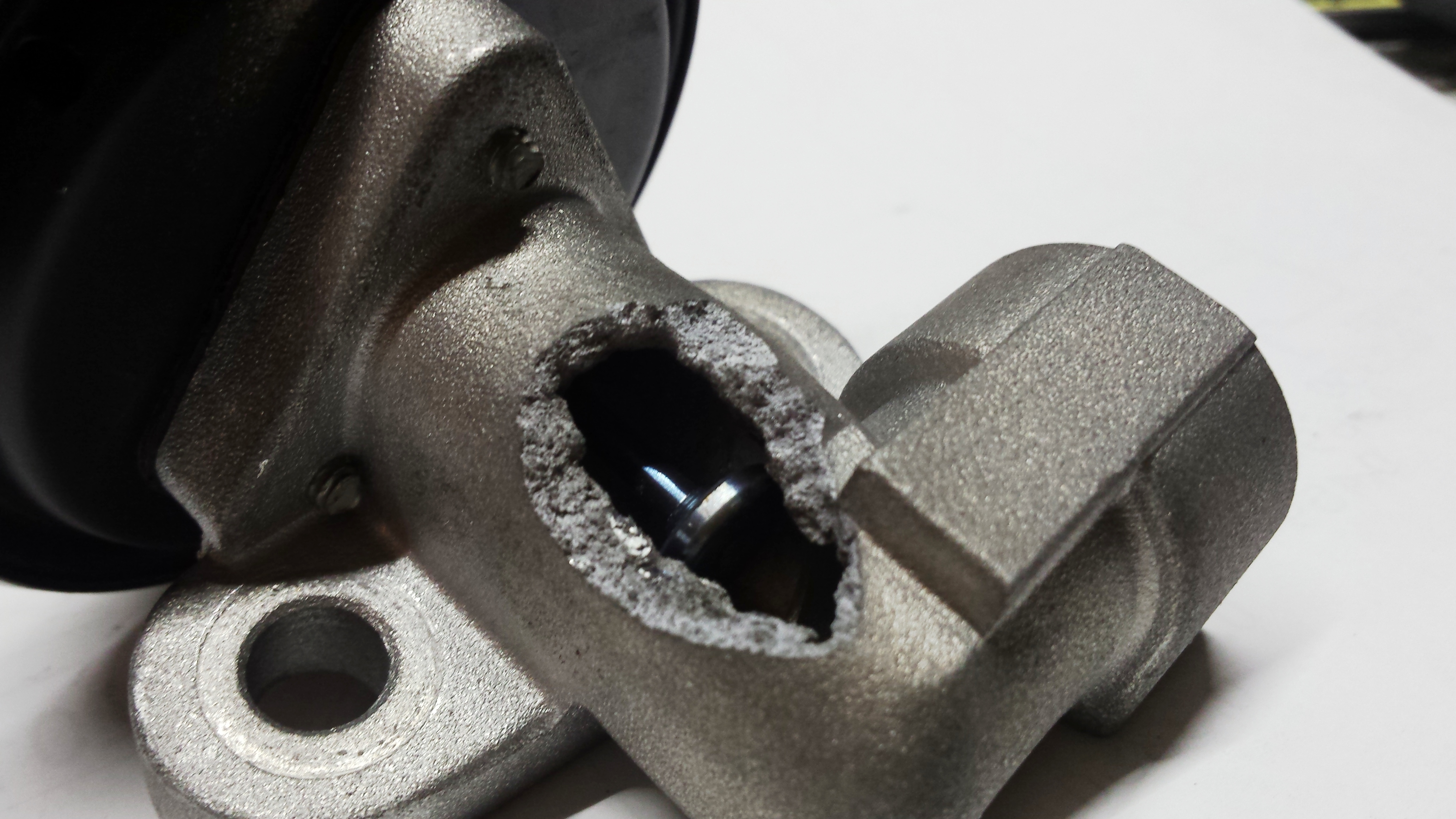

Kid's headed off to 3 day Event and gets about 30 miles away and something goes wrong. He goes back to tranny shop and they see the EGR valve has a huge hole blown in it. They replace it and check it over and good to go. Kid is back on the road again and go figure with in like 5 minutes the EGR Valve blows up again . Back to shop and they tell him take it home and return the blown EGR on Monday for refund. Tells him to check of debris in the Intake manifold of the feed tube going to exhaust.

Ok , I take of the EGR and go figure there are two melted vacuum lines . In half and self sealing . not sure what happened 1st the melted tubes or the Valve failure.

Tube is that hard walled plastic that you can't find to replace. watching videos and digging around nothing. Mcmaster Carr was thought, but what do others do. I see folks rigging with rubber tubing plastic elbows and wire ties.

I found some SS tubing. It's 316L and the right size 3/16" ID and some 1/8" ID . Was thinking about flaring the ends on the lathe ( low speed metal forming )

Tubing can fit them into the different coupling and then no worries about melting. Flaring is over kill but sounded like fun.

SS tubing a bad idea? Not seen it before on a Car / Truck. Figured I might be missing something really simple. Got Pictures I can post if you guys want, Figured most of you hate working on cars too.

( unless you can make a custom tool ) Thanks in advance.

Tell me if I'm fueling the train down the wrong track.

I'll try to be concise.

Kids 2001 Ford Escape 3.0 L Had a noise we thought might be tranny, we parked it for a while and needed to get it going andf ran it over to the Local Tranny shop. They looked at it and figured out it was an idler bearing for a belt. All done

Kid's headed off to 3 day Event and gets about 30 miles away and something goes wrong. He goes back to tranny shop and they see the EGR valve has a huge hole blown in it. They replace it and check it over and good to go. Kid is back on the road again and go figure with in like 5 minutes the EGR Valve blows up again . Back to shop and they tell him take it home and return the blown EGR on Monday for refund. Tells him to check of debris in the Intake manifold of the feed tube going to exhaust.

Ok , I take of the EGR and go figure there are two melted vacuum lines . In half and self sealing . not sure what happened 1st the melted tubes or the Valve failure.

Tube is that hard walled plastic that you can't find to replace. watching videos and digging around nothing. Mcmaster Carr was thought, but what do others do. I see folks rigging with rubber tubing plastic elbows and wire ties.

I found some SS tubing. It's 316L and the right size 3/16" ID and some 1/8" ID . Was thinking about flaring the ends on the lathe ( low speed metal forming )

Tubing can fit them into the different coupling and then no worries about melting. Flaring is over kill but sounded like fun.

SS tubing a bad idea? Not seen it before on a Car / Truck. Figured I might be missing something really simple. Got Pictures I can post if you guys want, Figured most of you hate working on cars too.

( unless you can make a custom tool ) Thanks in advance.