This will be the final installment (I hope) of the saga of the Grizzly Wood Mill backlash mystery, thanks especially Tom White for the help. Also, sdelivery, I don't know if you saw something specific but I think you hit it.

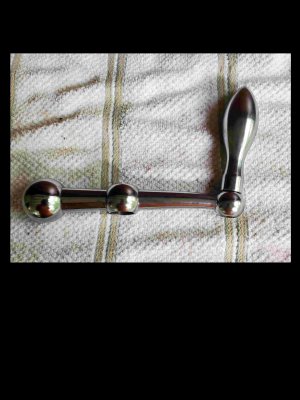

The final setup that kind of settled it for me was to mount the Y axis screw on the removed table. I clamped the Y axis outer bearing housing with the lead screw and handle all fitted as in the machine. This was mounted firmly to one end of the table with hold downs with the crank over the edge. I put the big nut cube on the lead screw and put a greased wood spacer block under it to get it on axis and be able to crank in and out. I could then operate the lead screw out of the machine and could see what was going on. The leadscrew is bent just a tiny bit- probably just 2 thousandths. You have your choice of cranking in on the antibacklash nuts to make it very stiff but ok on backlash or adjusting for free running and accepting .030 backlash. The original owner who owned it for 20 noted that the Y axis handle was a bit bent on arrival, this was much worse than thought. The shipper banged it in to "workable"- original owner had no experience and knew no better. The X axis moves like butter with a few thou of backlash, the Y axis runs somewhat smoothly at .03 or very stiff at anything less than 10. My notes from my presale inspection looked at spindle runout, I noted that the Y axis was a bit sloppy but reasoned that this was just adjustment since it had so few hours on it.

Final outcome- Grizzly had a Y axis leadscrew in stock for $205, kind of amazing, this thing hasn't been made for 15 years or more. Its on the way- I make a final final epilogue if its worth talking about.

Thanks to all that helped or spent time reading. This is a great board. Drink Ovaltine.