- Joined

- Dec 3, 2017

- Messages

- 1,905

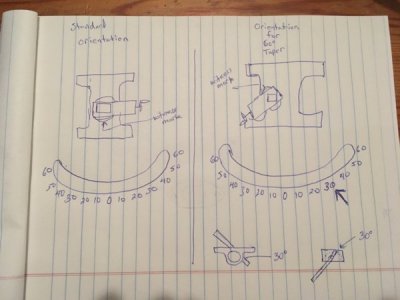

Ok, so I don’t really like to make tooling, but the budgets all used up and I have work to do. So here goes, and I know it’s not terribly complicated , but I need a little clarification I guess.

Making a “60 degree” dovetail cutter:

1:Turned shank to correct OD and length.

2:Found an insert that’ll probably work.

3:triangle insert is .616” per side, so I’m going with 1.200” major diameter on the cone shaped portion. Figure the insert needs relief, and I’d provide it that way.

4:watch every video and read every forum post I can find trying to decide if the compound should be set at 30 degrees or 60 degrees. Kinda decide it’s 30....then back out and do more searching and reading. Start getting frustrated it’s called a 60 degree cutter if I’m cutting a 30 degree taper. Start thinking I’m obviously not smart enough for this hobby. Remember there are people out here in the ether, that can clear it up with a 3 word sentence.

5 ost thread

ost thread

Making a “60 degree” dovetail cutter:

1:Turned shank to correct OD and length.

2:Found an insert that’ll probably work.

3:triangle insert is .616” per side, so I’m going with 1.200” major diameter on the cone shaped portion. Figure the insert needs relief, and I’d provide it that way.

4:watch every video and read every forum post I can find trying to decide if the compound should be set at 30 degrees or 60 degrees. Kinda decide it’s 30....then back out and do more searching and reading. Start getting frustrated it’s called a 60 degree cutter if I’m cutting a 30 degree taper. Start thinking I’m obviously not smart enough for this hobby. Remember there are people out here in the ether, that can clear it up with a 3 word sentence.

5