- Joined

- Jan 20, 2018

- Messages

- 5,615

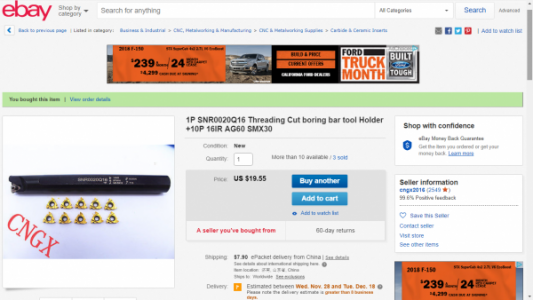

I just ordered this 16mm shank external threading tool with 10 inserts for less than $20 U.S.!

https://cgi.ebay.com/ws/eBayISAPI.dll?ViewItemVersion&item=173143881932&view=all&tid=1925610990007

I just can't believe how affordable this stuff is. Based on my recollections (late 20th century), I never expected to be able to buy this kind of tooling.

I've been quite pleased with the other Chinese made tools & inserts I've purchased. Expect the same on this one. At the rate I'm going, this should be a lifetime supply of inserts.

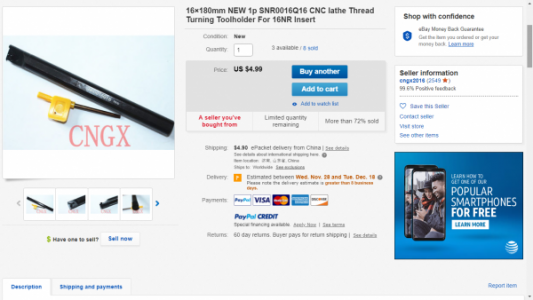

Now I'm shopping for internal threading bars.

https://cgi.ebay.com/ws/eBayISAPI.dll?ViewItemVersion&item=173143881932&view=all&tid=1925610990007

I just can't believe how affordable this stuff is. Based on my recollections (late 20th century), I never expected to be able to buy this kind of tooling.

I've been quite pleased with the other Chinese made tools & inserts I've purchased. Expect the same on this one. At the rate I'm going, this should be a lifetime supply of inserts.

Now I'm shopping for internal threading bars.