-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FABRICATING part spheres 3mm

- Thread starter stuarth44

- Start date

- Joined

- Dec 20, 2012

- Messages

- 9,422

Sorry to hear about the stroke, Stu, but it looks like you're doing pretty well in spite of it.

Master craftsmen like you are a rarity in our throw away world. It was really refreshing to listen to you speak about doing bespoke things so easily that the vast majority of us cannot do. I really hope there is some young guy who takes you up on your offer to learn from you so that your wonderful skills are not lost.

Welcome to HM!!

Master craftsmen like you are a rarity in our throw away world. It was really refreshing to listen to you speak about doing bespoke things so easily that the vast majority of us cannot do. I really hope there is some young guy who takes you up on your offer to learn from you so that your wonderful skills are not lost.

Welcome to HM!!

- Joined

- Jan 22, 2020

- Messages

- 197

Aww, Shucks, thank you so muchelySorry to hear about the stroke, Stu, but it looks like you're doing pretty well in spite of it.

Master craftsmen like you are a rarity in our throw away world. It was really refreshing to listen to you speak about doing bespoke things so easily that the vast majority of us cannot do. I really hope there is some young guy who takes you up on your offer to learn from you so that your wonderful skills are not lost.

Welcome to HM!!

- Joined

- Feb 9, 2017

- Messages

- 5,240

Welcome Stuart. I hope you can keep on with doing YouTubes as there's no way I'm going to make it to Oz any time soon. I love doing metal forming and have been slowly gathering my tools and watching YouTubes. You seem to have a different technique/method than the others I've seen. Would love to see your workstation in action as I can only assume how it works. I've also not seen a Urethane upper wheel. Seen them used on lowers and on beaders.

- Joined

- Jan 22, 2020

- Messages

- 197

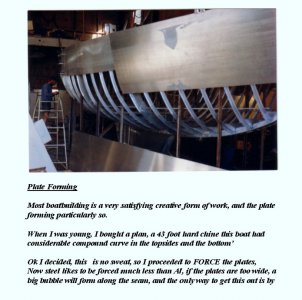

thanks, in NZ i had a big former with 5 ft throat, the plates up to 20 feet long would travel hanging from a chain hookup on an overhead monorail, by using the up down on the chain hoist i could do 4 plates a day, alone, first to stretch, giving the [plate what i call longtitudanal Banana , so lengthwise it could wrap along the boat, then completing the form using vee poly up to 6mm alu, then vee steel for 8--12 plate, the whole plate is covered, with a stack of wood templates by my side as shape alters quickly on 40 foot hull, NZ was the first place to use these wheels like that, somewhere i have a photo, travel speed from memory 1 foot 3 seconds, by the way, it is not a difficult thing to do, to raise the plate you just went up a lil then jog down to run parralel here i am a younger manWelcome Stuart. I hope you can keep on with doing YouTubes as there's no way I'm going to make it to Oz any time soon. I love doing metal forming and have been slowly gathering my tools and watching YouTubes. You seem to have a different technique/method than the others I've seen. Would love to see your workstation in action as I can only assume how it works. I've also not seen a Urethane upper wheel. Seen them used on lowers and on beaders.