-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

[Lathe] Fanuc OT to DC_CNC conversion

- Thread starter JimDawson

- Start date

- Joined

- Feb 8, 2014

- Messages

- 11,144

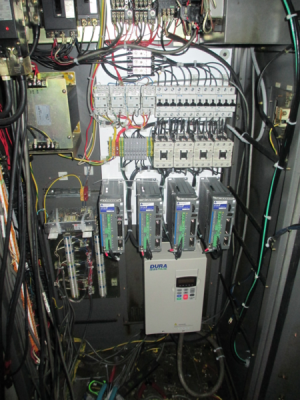

Another update. The servo panel is now installed and a bunch of other wiring done.

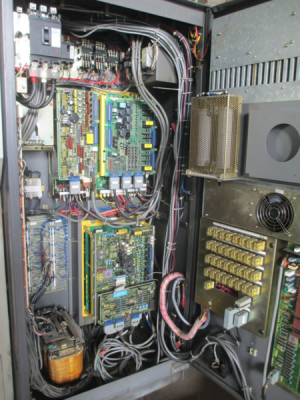

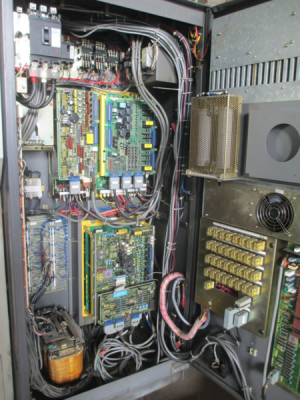

The before pic

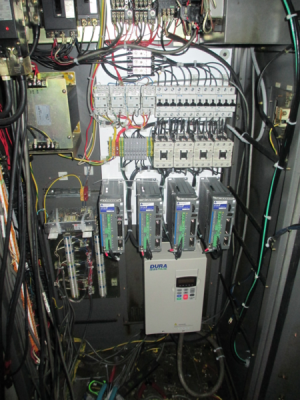

and after. Still need to do some wiring cleanup. At this point I have re-wired the entire machine, none of the original control wiring exists, only the power components remain the same.

I could actually run the spindle motor right now, but not quite ready for that yet.

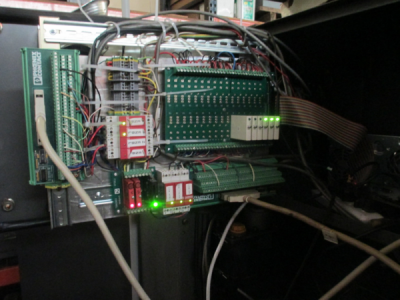

The X axis servo setting in place just to check fit and cable length.

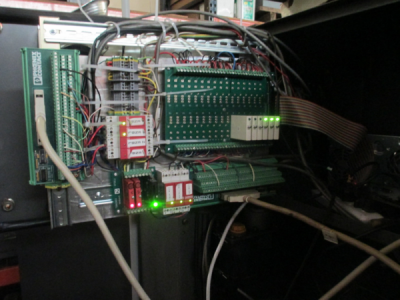

Have a few blinky lights powered up, another couple dozen wires to land on this panel then I can button it up. All that's left is the control and encoder wiring to the servo drives and the control power and e-stop buttons. All of the other I/O wiring is complete. Waiting on the cables for the encoders and servo controls, I screwed up and ordered the wrong ones, so I won't have the new ones until early next week.

Hopefully I'll start turning the wheels next week.

The before pic

and after. Still need to do some wiring cleanup. At this point I have re-wired the entire machine, none of the original control wiring exists, only the power components remain the same.

I could actually run the spindle motor right now, but not quite ready for that yet.

The X axis servo setting in place just to check fit and cable length.

Have a few blinky lights powered up, another couple dozen wires to land on this panel then I can button it up. All that's left is the control and encoder wiring to the servo drives and the control power and e-stop buttons. All of the other I/O wiring is complete. Waiting on the cables for the encoders and servo controls, I screwed up and ordered the wrong ones, so I won't have the new ones until early next week.

Hopefully I'll start turning the wheels next week.

- Joined

- Oct 14, 2014

- Messages

- 1,966

Looking GREAT. Once you prove this equipment out, I want to do one.

Just remember the engineer's project time rule:

the first 90% of the project takes 90% of the time

the last 10% of the project takes the other 90% of the time

Just remember the engineer's project time rule:

the first 90% of the project takes 90% of the time

the last 10% of the project takes the other 90% of the time

- Joined

- Feb 8, 2014

- Messages

- 11,144

Jim, what a major project. Your wiring looks great.

Thank you. It did turn into a bit more of a project than I intended in the beginning.

- Joined

- Nov 25, 2015

- Messages

- 8,234

well , now that you bought the Hass, what's going to happen with this? Are you going to finish it?

Congrats on the Haas. I hope you finish this project.

Congrats on the Haas. I hope you finish this project.

- Joined

- Feb 8, 2014

- Messages

- 11,144

well , now that you bought the Hass, what's going to happen with this? Are you going to finish it?

Congrats on the Haas. I hope you finish this project.

Thank you.

Absolutely the lathe is going to get finished. In fact it's nearing completion, I've spent the day running and terminating the control and encoder cables for the servo drives. About all that's left to do is wire in the push buttons for the control power and E-stop systems, and clean up a few odds & ends. Then I can turn power on and get the servo motors under control before I connect them mechanically to the machine.

After that comes the real fun, getting the software to actually run the machine. I think what I have written will work, but there is always debugging to do.

- Joined

- Feb 8, 2014

- Messages

- 11,144

An update:

The lathe is coming along, I haven't posted much because nothing too visually interesting is happening, just connecting a lot of little wires. What fun is a post without interesting pictures?

Saturday and Sunday was spent proving out all of the power systems and hydraulics. One milestone was met last evening, I have one of the servo motors under control of the Galil card. Took a bit to learn how to do it, I've never used DMM drives before and some of the control is not totally intuitive. I could have done it quicker but I was running a job on the mill and helping install the new Haas mill at the same time. The spindle motor will be fired up tomorrow when I get the comm cable from Automation Direct.

I'll get the other 3 servos bench tuned today. I expect that by the end of the week all of the electrical systems and servos will be installed, operational, and under computer control. Then comes the software debugging process.

Stay tuned.......... Chips coming soon.

The lathe is coming along, I haven't posted much because nothing too visually interesting is happening, just connecting a lot of little wires. What fun is a post without interesting pictures?

Saturday and Sunday was spent proving out all of the power systems and hydraulics. One milestone was met last evening, I have one of the servo motors under control of the Galil card. Took a bit to learn how to do it, I've never used DMM drives before and some of the control is not totally intuitive. I could have done it quicker but I was running a job on the mill and helping install the new Haas mill at the same time. The spindle motor will be fired up tomorrow when I get the comm cable from Automation Direct.

I'll get the other 3 servos bench tuned today. I expect that by the end of the week all of the electrical systems and servos will be installed, operational, and under computer control. Then comes the software debugging process.

Stay tuned.......... Chips coming soon.

- Joined

- Feb 8, 2014

- Messages

- 11,144

IT'S ALIVE !!!!!  All of the servos are installed and under computer control. Everything moves as planned.

All of the servos are installed and under computer control. Everything moves as planned.

Here is the Z motor mount my son built to adapt the new servo motor.

And the last servo to be installed, the Z axis.

And the wide view, looking at the spindle motor, and the back of the spindle with the collet closer

Then one of the most important systems on the machine.......

.

.

.

.

The stereo system ( above the monitor ) (the box between the speakers will house the USB ports, not installed yet)

(the box between the speakers will house the USB ports, not installed yet)

And a video of the turret rotating, not much going on here, but at least it works.

All of the servos are installed and under computer control. Everything moves as planned.

All of the servos are installed and under computer control. Everything moves as planned.Here is the Z motor mount my son built to adapt the new servo motor.

And the last servo to be installed, the Z axis.

And the wide view, looking at the spindle motor, and the back of the spindle with the collet closer

Then one of the most important systems on the machine.......

.

.

.

.

The stereo system ( above the monitor )

(the box between the speakers will house the USB ports, not installed yet)

(the box between the speakers will house the USB ports, not installed yet)

And a video of the turret rotating, not much going on here, but at least it works.

- Joined

- May 7, 2014

- Messages

- 776

...and you have lost what... 20Lbs? so cool! Thanks for alyway's posting just great material and picks! No clue how you find the time.

Jeff and Mitch.

Jeff and Mitch.