Hi Yuriy, it's been ages since I was part of the first beta group so I'm glad to see you're still doing well with this amazing product.

I have a TouchDro TI with AccuRemote scales here. For some reason I never looked much at the feed rate display before now but I've recently been using it with a new face mill to find the best S&F for a good finish. I noticed that even when I'm driving the X axis with a drill so that the feed rate is really constant, the feed rate display makes big jumps, like it will show 7 in/min then jump to 12, then down to 4. I only have two magnets for the hall effect sensor. Could that be why it jumps around so much? I'll note that the tach function is rock steady.

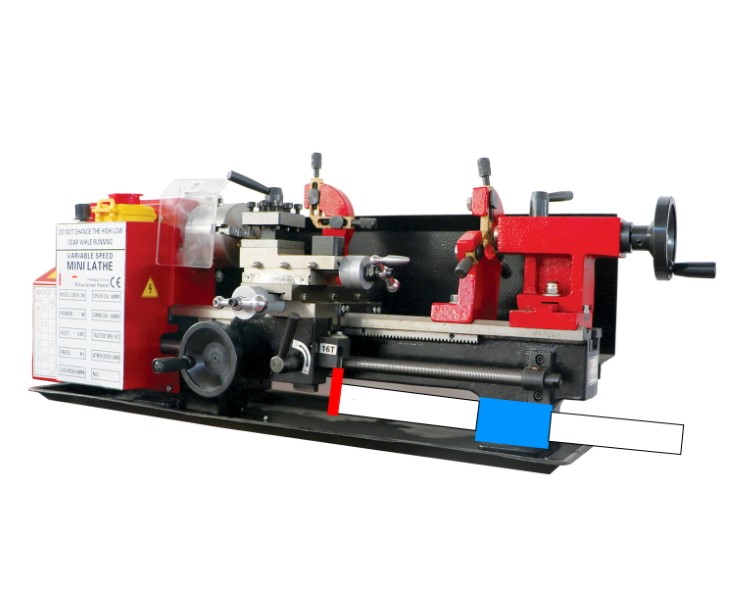

And while I have you....I want to put another scale on my mini lathe, attached to the carriage. Given the small amount of room on a 7x10, I was thinking of hanging one end of the scale on the right side of the carriage and then mounting the read head solidly to the lathe bed. That would mean that the scale bar would not have a mount on the other end, instead using the head unit as a defacto mount. Do you see any issue with wear or accuracy doing it this way? I made up a quick and dirty mockup to illustrate.

I have a TouchDro TI with AccuRemote scales here. For some reason I never looked much at the feed rate display before now but I've recently been using it with a new face mill to find the best S&F for a good finish. I noticed that even when I'm driving the X axis with a drill so that the feed rate is really constant, the feed rate display makes big jumps, like it will show 7 in/min then jump to 12, then down to 4. I only have two magnets for the hall effect sensor. Could that be why it jumps around so much? I'll note that the tach function is rock steady.

And while I have you....I want to put another scale on my mini lathe, attached to the carriage. Given the small amount of room on a 7x10, I was thinking of hanging one end of the scale on the right side of the carriage and then mounting the read head solidly to the lathe bed. That would mean that the scale bar would not have a mount on the other end, instead using the head unit as a defacto mount. Do you see any issue with wear or accuracy doing it this way? I made up a quick and dirty mockup to illustrate.