Thanks for the posts I’ll definitely be building something similar for my setup. Will be much needed after dealing with a shaky stand.

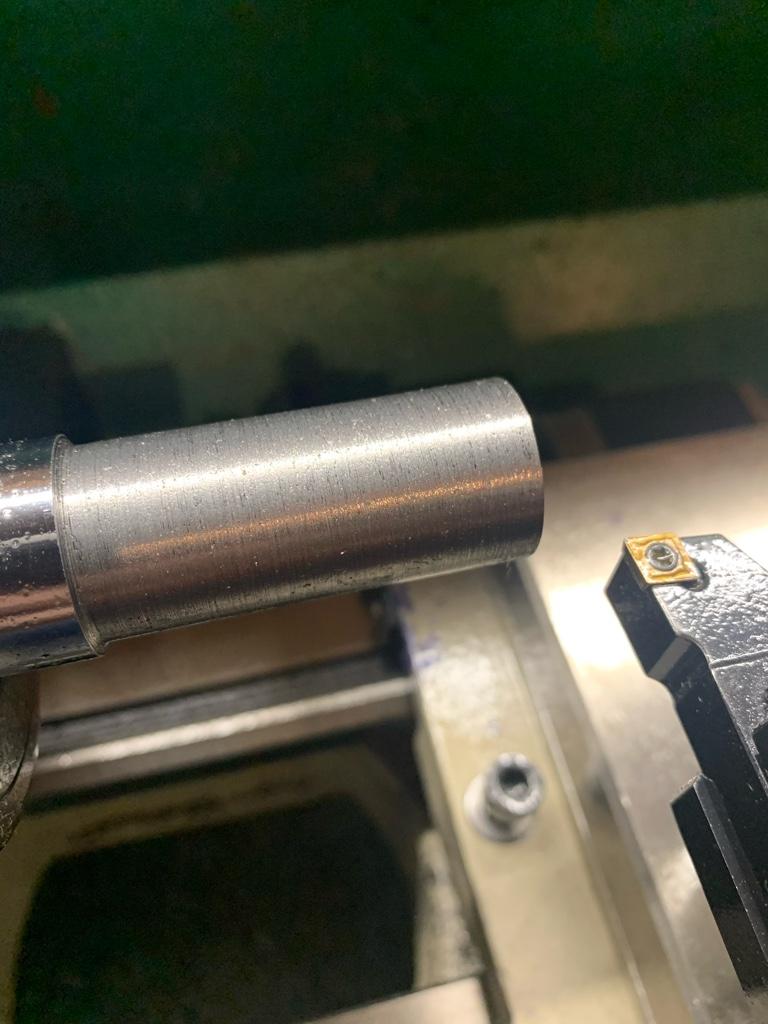

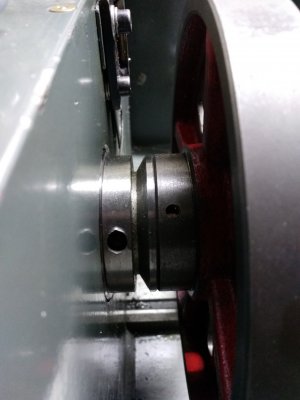

For the collet chuck, I can take a picture of the backplate but their is not enough room to machine a collar that’ll be long enough. I checked the chuck’s taper with a dial indicator and the runout wasn’t too bad, about .002 with no set tru adjustments. Is that decent for an er40 chuck or would the backplate be worth it to get less runout or what concerns should I have when using this setup?

For the collet chuck, I can take a picture of the backplate but their is not enough room to machine a collar that’ll be long enough. I checked the chuck’s taper with a dial indicator and the runout wasn’t too bad, about .002 with no set tru adjustments. Is that decent for an er40 chuck or would the backplate be worth it to get less runout or what concerns should I have when using this setup?

Last edited: