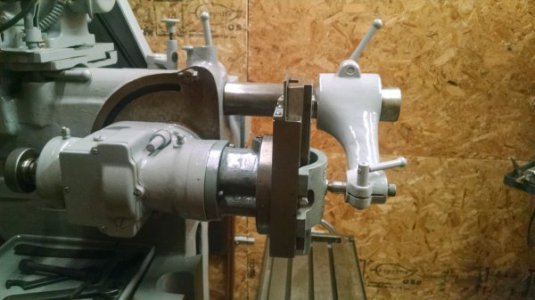

Finally picked up a slotter attachment that I have been looking for. Probably paid a bit much, but it's practically new. Stripped it and cleaned out the old gunk. Back together already, quickest rebuild yet. Missing one oil cap and the arbor, but I have a print for the arbor. All I did was clean it.

Jason

Jason