guitarman,

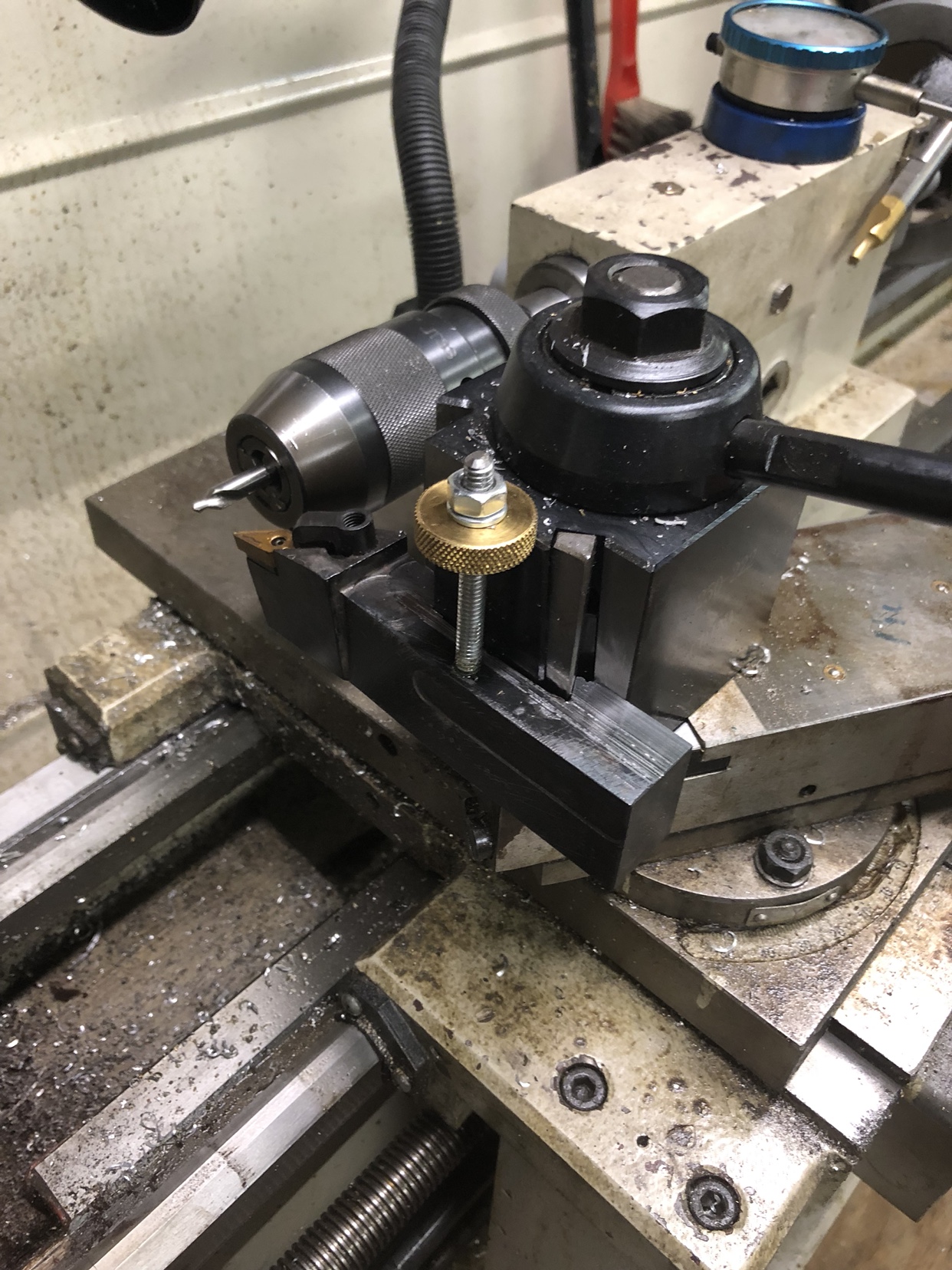

Nice looking work. But one comment on how you have the QCTP and compound set. With the compound, it's personal preference unless you are cutting threads. But I usually set the compound around to 30 degrees. That way, you can advance the cutter when turning without having to unlock the cross feed lock and when facing without having to unlock the carriage lock, which should always be set while facing, grooving or parting off.

The QCTP, however, should always be set square to the spindle axis, normally with one mounting face facing the work and the other on the left (headstock) side of the TP. The only time that it would be set otherwise would be rotated clockwise 90 degrees if you need to work up close to the tailstock. With it set rotated a few degrees clockwise as it appears to be in your photograph, (a) the horizontal angles won't be what the cutter or the insert was ground for and (b) you can't safely work right up next to the chuck jaws. The quick and dirty way to align it is to slightly loosen the nut on the hold down stud so that you can rotate the TP but it won't slide around. Chuck up any piece of solid round that you have handy. Remove whatever cutter holder you have mounted, leaving the lever on the TP in the loosen position if you have a piston type TP or the tightened position with a wedge type.. Then, with the cross slide, run the TP out against the round bar. which should square it up. While the TP is pressed up against the round bar, re-tighten the hold-down nut.