- Joined

- Feb 2, 2013

- Messages

- 3,625

here is Steffan Gottswinter's version

Nice Work Jeff!!!

Nice Work Jeff!!!

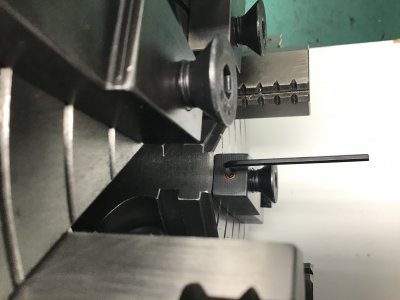

NICE JOB!!!!I saw Tom Lipton's version and simplified it to my hobby shop standards.

4140 was the material I used.

The pieces were hardened today using an oxy acetylene torch and light oil.

Everything fits correctly. I'm pretty happy with the end product, this was a bit of a stretch for me.

I was looking for consistency and proper function. I give myself a C- for the overall project. The first prototype has much larger chamfers.

I learned a bunch, better next time.View attachment 309546View attachment 309547View attachment 309548View attachment 309549

David and Mike,

Did you really need to show Robin and Steffan’s videos?

Now I really feel inadequate.

I made some T nuts for my rotary table that fit after I thinned them down by .100”

The pics show the whole set up.

Jeff,David and Mike,

Did you really need to show Robin and Steffan’s videos?

Now I really feel inadequate.

I made some T nuts for my rotary table that fit after I thinned them down by .100”

The pics show the whole set up.