-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

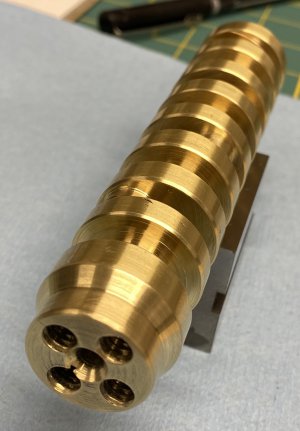

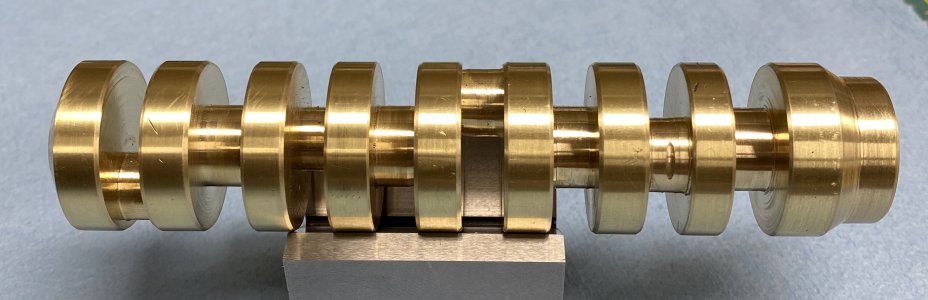

Finished my first eccentric turn- Brass crankshaft

- Thread starter Janderso

- Start date

- Joined

- Oct 18, 2016

- Messages

- 2,872

This was a fun project. I learned about three different ways of offsetting the part in the lathe.

I did gain some confidence which is always a bonus.

Would you like to tell us how you did the offsets?

- Joined

- Mar 26, 2018

- Messages

- 8,386

This is just a piece that will serve as a paper weight. I wanted to try to figure out how to set up and turn an eccentric.

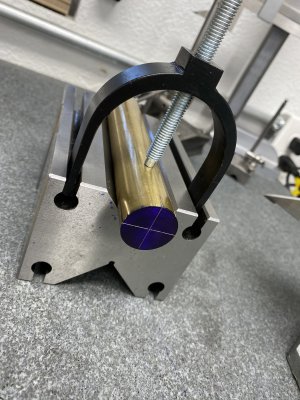

I cut a bevel in 10-24 cap screws. Used my mill and DRO to drill and tap the off set every 90 degrees.

I used 190 as the rpm. I didn’t want to go any faster than that. I used an insert style it off blade and a brazed carbide profile to clean up the edges. It was finicky work. Made a few mistakes in the finish but I wasn’t too worried about it.

I cut a bevel in 10-24 cap screws. Used my mill and DRO to drill and tap the off set every 90 degrees.

I used 190 as the rpm. I didn’t want to go any faster than that. I used an insert style it off blade and a brazed carbide profile to clean up the edges. It was finicky work. Made a few mistakes in the finish but I wasn’t too worried about it.

Attachments

-

DC1AFE40-A864-4172-8022-A937F6498271.jpeg719.7 KB · Views: 29

DC1AFE40-A864-4172-8022-A937F6498271.jpeg719.7 KB · Views: 29 -

80EA2CBD-4D7C-45D7-AB57-98BFDFB27FF8.jpeg621.3 KB · Views: 36

80EA2CBD-4D7C-45D7-AB57-98BFDFB27FF8.jpeg621.3 KB · Views: 36 -

5831B4D6-7ECF-404A-B66D-2C162CB35500.jpeg1.6 MB · Views: 37

5831B4D6-7ECF-404A-B66D-2C162CB35500.jpeg1.6 MB · Views: 37 -

B14A442B-7812-4393-A099-BA546350E1A9.jpeg1.4 MB · Views: 37

B14A442B-7812-4393-A099-BA546350E1A9.jpeg1.4 MB · Views: 37 -

BEA82573-A95C-46BD-8D24-397E4AAFB974.jpeg439.1 KB · Views: 31

BEA82573-A95C-46BD-8D24-397E4AAFB974.jpeg439.1 KB · Views: 31 -

0E6ACE77-5594-4E7D-AD55-618A29880391.jpeg420.5 KB · Views: 31

0E6ACE77-5594-4E7D-AD55-618A29880391.jpeg420.5 KB · Views: 31

- Joined

- Mar 26, 2018

- Messages

- 8,386

I should have made the rod journals like a typical four cylinder but I just turned them at 90 degree intervals as shown in the pic. I marked them 1-4 . Rolling it across a table is satisfying to see the mechanical action.Neat looking piece, is there a TDC order for the rod journals?

Sent from my iPhone using Tapatalk

- Joined

- Feb 5, 2018

- Messages

- 636

That looks really good. Now get to figuring out the connecting rods to fit.

Joe Hynes

Joe Hynes

- Joined

- Nov 11, 2017

- Messages

- 77

That's a cool part and your post is timely for me in that I plan to tackle a Sterling engine project soon and I'll have to make a crankshaft with multiple throws but not as complicated as what you've done. I'm still gathering materials and finding that brass is really expensive.

- Joined

- Mar 26, 2018

- Messages

- 8,386

Good old Youtube. You can find many examples on eccentric turning. The 4 jaw offset with an indicator was my first choice, then I saw one where he pinned the two ends accordingly.

I've thought a model steam engine. That looks like fun.

The grand kids are pretty young yet but I would love to spend some time with one of them in my shop learning together.

It's a great experience for our youth.

I've thought a model steam engine. That looks like fun.

The grand kids are pretty young yet but I would love to spend some time with one of them in my shop learning together.

It's a great experience for our youth.