- Joined

- Dec 8, 2017

- Messages

- 16

I recently purchased an Avid CNC Benchtop Pro, and spent the last month or two wiring up a CNCDepo S30C spindle + Fogbuster and all the associated extra bits (relays, solenoids, low pressure sensors, etc). Finally got it into a state where I could test it and make some chips!

Ran some straight cut tests and managed to get up to ~8in² MRR... but was too chicken to push it further. Also tried a few more realistic tests cutting out a little puzzle piece, which went mostly ok barring a silly slotting mistake. As it turns out, Fusion has an extra parameter for ramp speed on 2D contour which I didn't realize, so while the cutting feed rate was configured correctly it was trying to ramp down at 13ipm. And immediately welded up

That said, I'm super happy how the machine is performing so far! Seems I can hit ~150ipm in aluminum easily. The biggest problem is simply weight of the machine and table... those high accelerations really throw the table around. I think I'll back off feeds and keep it closer to 80 which seems more manageable. I have some plans to bolt the machine directly to the table, and reinforce the table a bit more which will probably help.

I have a bunch of end mills I would like to test out, see which gives nicest finish and least chatter, etc. Would also like to try some mild steel, maybe high carbon steel, and just see how it goes. Not holding my breath for that to go too well though

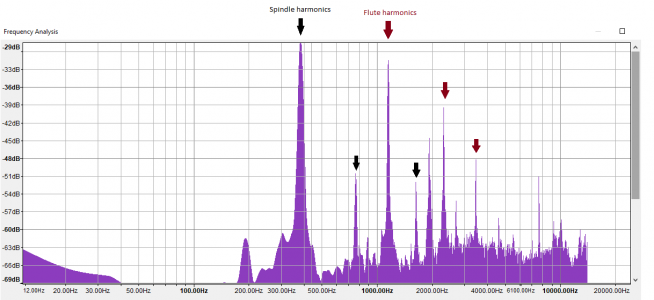

Along the way I decided to do some spectrographic chatter analysis for fun. E.g. here is a slice of the spectrum from during a cut, and you can identify both the spindle harmonics and the flute harmonics which I think is pretty neat.

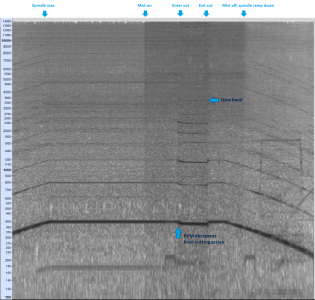

You can also look at the full spectrogram for the entire recording and see events like spindle ramp up/down, fogbuster turning on, entering and exiting the cut. You can even see where the spindle bogs down a little in the cut, because the frequency of the spindle harmonics reduce slightly in the cut and then bounce back after exiting. Because rotation is directly tied to the frequency in the spectrogram, we could theoretically calculate how much it bogged down