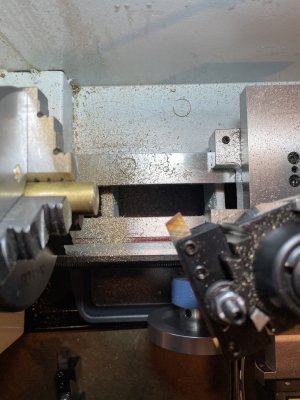

The compound shouldn't be moving at all. You can go ahead and tighten the gibs up enough to lock the compound so it can't move.

For facing you only need the saddle and the cross slide.

If it helps you can set the compound 90 degrees from the saddle so that the compound lead screw is parallel with the ways of the bed.

I keep the compound on my lathe snugged up tight for most operations. I only use it for threading and cutting tapers. The rule of thumb is to lock down any moving parts you don't need for that operation, it helps with over all rigidity. Keep parts that need to slide just loose enough to move without forcing.

For facing you only need the saddle and the cross slide.

If it helps you can set the compound 90 degrees from the saddle so that the compound lead screw is parallel with the ways of the bed.

I keep the compound on my lathe snugged up tight for most operations. I only use it for threading and cutting tapers. The rule of thumb is to lock down any moving parts you don't need for that operation, it helps with over all rigidity. Keep parts that need to slide just loose enough to move without forcing.