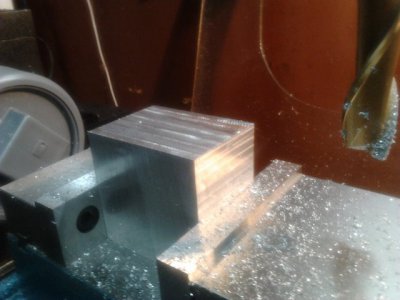

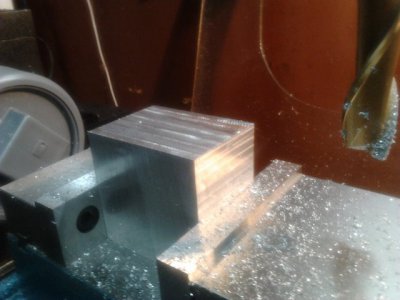

Thanks Rick! I havent done a ton last day or two as I've been busyier, But the weekend is HERE!! ::thumbzup:: I did get a chunk of 2.5 inch stock squared and faced the ends to be used as the rear crancase section. I had origionally planned this to be one piece, But after thinking about how much metal removal it would take I decided to make it 2 pieces.....One being the "snout" with the brass bushing and holding the crank and carb, And 1 block the cylinder is mounted on top of and will have mount lugs and by being seperate will eliminate the need for the traditional rear cover to keep the rod on the crankpin. I'm fixing to go out and put some holes in it now  Todd

Todd

Last edited by a moderator: