- Joined

- Oct 4, 2021

- Messages

- 13

Don't overlook buying used equipment. Craig's List and Facebook Marketplace can have some pretty sweet deals. As someone posted, you can plan on spending more money on tooling and tools than the base machine.

I'm guessing that if you are just first starting to learn and will probably want a larger machine down the road. And then you'll want a milling machine. And then you'll want a xyz. So my suggestion is to start off with a cheaper, used machine to start learning on. Pick up used tools and tooling as well. Once you get some experience you'll know better what machine(s) you want to end up with for your gunsmithing work.

I still use tools that I bought from retired toolmakers back in the 70's every day. Those older quality tools will last forever if you treat them properly. You can find deals on complete sets of tools for what a few new tools would cost. Also, invest in a few good books and watch a lot of YouTube videos.

A journey of a thousand miles.......

Have fun!

Ted

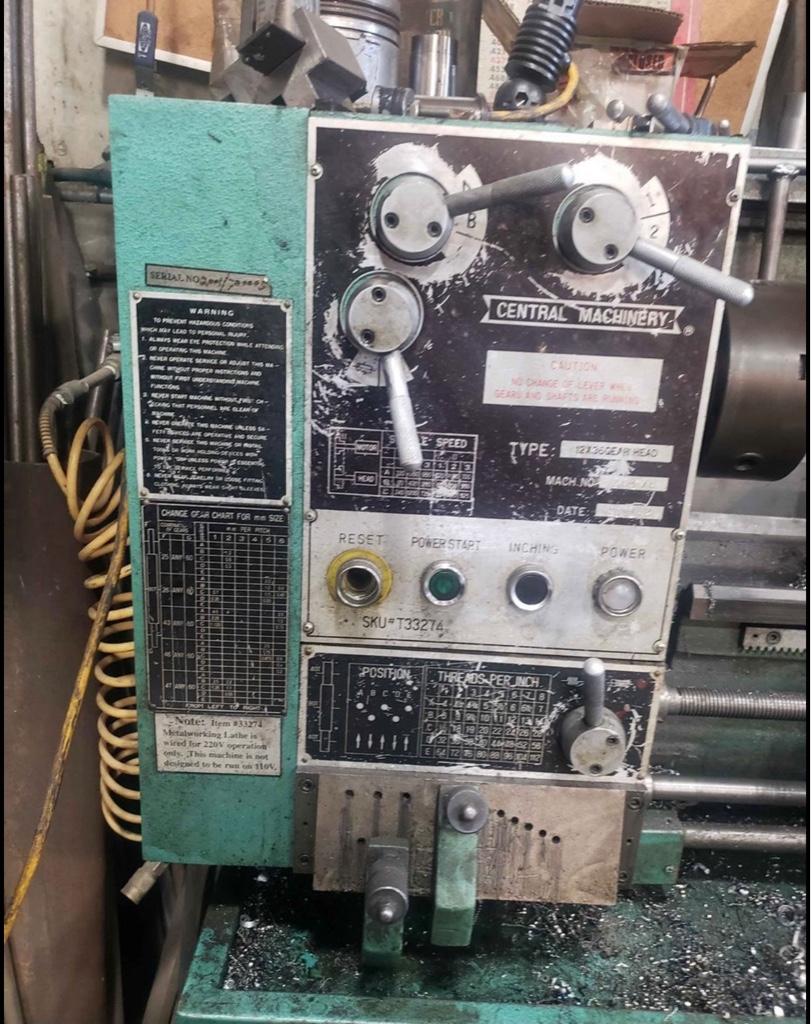

Thanks for the tips, I’ve been keeping an eye out for any local gems. I actually just saw this one posted in the last day. Looks like it’s a Central Machinery 33274, 12x36. With something used like this, I wouldn’t mind leaving in the garage as much.

Does this seem like a viable machine? They said it’s in working condition, trying to determine the price still.

I’m fine with getting a new smaller one to start, as I think it’s be useful to keep around anyway and would fit well in my current shop. However, I’m open to reasonable ideas like this for sure.