-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

B

BRIAN

Forum Guest

Register Today

Now is time for an admission I am so frightened of making a error that I check everything I do in as many ways as possible

So when I started to make the jigs for this project I was worried about errors when spacing the fins on the barrel and the head

so I made a small test piece that when placed on the surface of the slitting saw located in the previous cut so that every time I

changed the settings I had a tool to prove it was OK.

Today was the day I was setting the saw to 21.6mm depth after getting it on the money I slavishly applied my tool and CLUNK.

it refused to go in the slot. Horrified I checked the settings, And I found I had been so intent on getting the .6 correct I had

inadvertently set to 20.6 mm.

Now you may say that ,surely you would have noticed that, yes but probably, only after I had cut about 1/4 of the cut One tends to get a

bit over confident when doing repetitive work

So 15 minutes making the tool, Saved two days making a new head.

Brian

So when I started to make the jigs for this project I was worried about errors when spacing the fins on the barrel and the head

so I made a small test piece that when placed on the surface of the slitting saw located in the previous cut so that every time I

changed the settings I had a tool to prove it was OK.

Today was the day I was setting the saw to 21.6mm depth after getting it on the money I slavishly applied my tool and CLUNK.

it refused to go in the slot. Horrified I checked the settings, And I found I had been so intent on getting the .6 correct I had

inadvertently set to 20.6 mm.

Now you may say that ,surely you would have noticed that, yes but probably, only after I had cut about 1/4 of the cut One tends to get a

bit over confident when doing repetitive work

So 15 minutes making the tool, Saved two days making a new head.

Brian

B

BRIAN

Forum Guest

Register Today

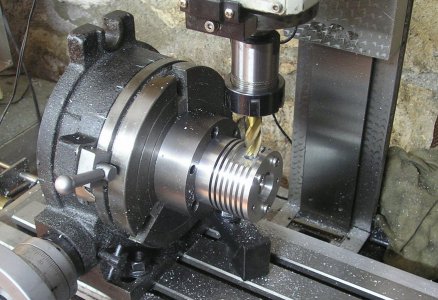

The last radial fins have been cut leaving only the fins on the top of the head to be cut at a later date

The top two fins are cut to twice the depth of the others being clear of the ports and clamping force from the cylinder bolts ETC.

I think the mill might be due for a clean??

Slowly slowly Brian.

The top two fins are cut to twice the depth of the others being clear of the ports and clamping force from the cylinder bolts ETC.

I think the mill might be due for a clean??

Slowly slowly Brian.

- Joined

- Sep 19, 2014

- Messages

- 234

Looks great so far! Thanks for updating your progress

- Joined

- Jan 20, 2013

- Messages

- 272

I think the mill might be due for a clean??

Is there a mill under those chips? ;-) Dave

B

BRIAN

Forum Guest

Register Today

B

BRIAN

Forum Guest

Register Today

Happy new year to you all.

Brian.

Brian.