- Joined

- Nov 3, 2018

- Messages

- 12

I had a new project at work to make a custom coms tower not big, just 15m. For my other towers I made a jig they range from 20 to 50m but for this tower I had to build the sections around an existing tower leaving the antennas on till we could move them back onto new tower thus not to disrupt clients.

Right options :

1) could have moved site. Land owner refused

2) build new jig for a once off job. The jig would take just as long to make as the tower itself.

3) let's start using my not so good but loving the fun machining skill.

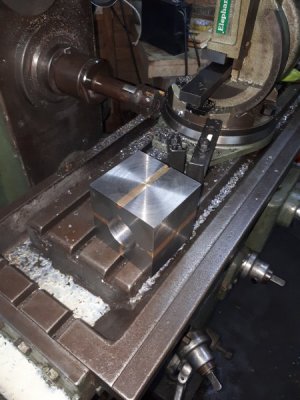

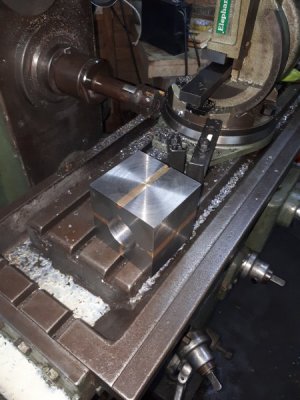

Ok 210 flat connection flanges need to be welded onto round tubes, I was not going to try this with ruler and fingers. So made this:

This was made from 4 pieces of square bar that I machined to size to slide along the tube to hold each flange in place and keep them at exactly 60deg. Here are the rest of the pics to tell the story.

Right options :

1) could have moved site. Land owner refused

2) build new jig for a once off job. The jig would take just as long to make as the tower itself.

3) let's start using my not so good but loving the fun machining skill.

Ok 210 flat connection flanges need to be welded onto round tubes, I was not going to try this with ruler and fingers. So made this:

This was made from 4 pieces of square bar that I machined to size to slide along the tube to hold each flange in place and keep them at exactly 60deg. Here are the rest of the pics to tell the story.