- Joined

- Feb 2, 2014

- Messages

- 1,060

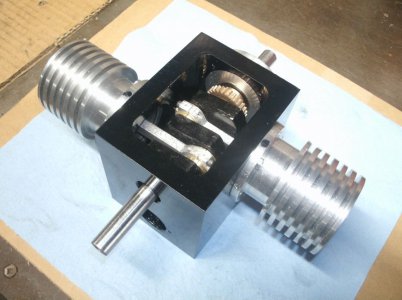

You are right as you can see I was almost done when I realized I had forgot the step. Nothing else to do but just start over.

The liners are made from cast iron and they sure cut nice but what a mess to clean up.

This is cylinder two and the liner for it.

I roughed out the connecting rods but no picture. That's where I will start next.

Thanks for looking

Ray

The liners are made from cast iron and they sure cut nice but what a mess to clean up.

This is cylinder two and the liner for it.

I roughed out the connecting rods but no picture. That's where I will start next.

Thanks for looking

Ray