- Joined

- Aug 7, 2018

- Messages

- 668

Hi Terry,

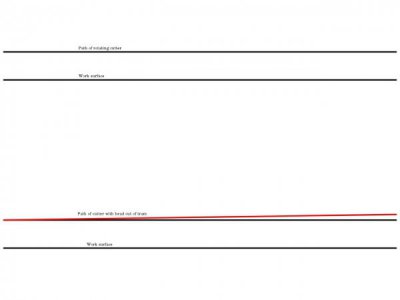

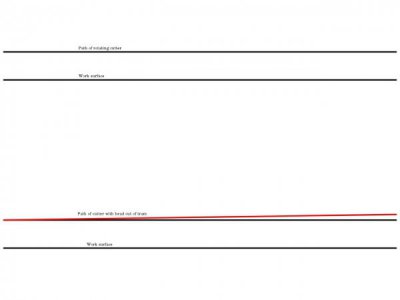

If you think about it, The single cutting edge of any rotating tool has to be absolutely perfectly parallel to the work surface in order not to make a second cut. Since this is almost impossible to achieve, particularly on a hobby machine, there will always be two cuts 180 degrees apart unless the machine head is canted, ie out of tram.

If you look at the cutter path at the bottom, the red line shows the path the cutter takes if the mill head is out of tram. The cutter will clear the work when moving one way and take a second cut when moving the other way.

This applies to any rotating tool.

Bottom line is that regardless of design, ANY fly cutter should be constructed in such a way that the cutting tip only engages the work piece once per revolution. A properly constructed Type 1 or Type 2 will accomplish that.

If you think about it, The single cutting edge of any rotating tool has to be absolutely perfectly parallel to the work surface in order not to make a second cut. Since this is almost impossible to achieve, particularly on a hobby machine, there will always be two cuts 180 degrees apart unless the machine head is canted, ie out of tram.

If you look at the cutter path at the bottom, the red line shows the path the cutter takes if the mill head is out of tram. The cutter will clear the work when moving one way and take a second cut when moving the other way.

This applies to any rotating tool.