- Joined

- Apr 14, 2014

- Messages

- 3,140

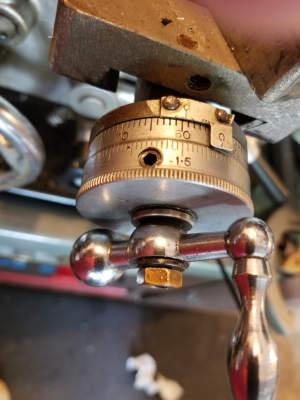

I think it's the one missing from the ratchet mechanism on my 6" Starrett micrometer. I was disassembling it last week to replace the pin. The spring was stuck in the bore so I started wiggling it with a dental tool. Suddenly it shot out. I looked for hours but couldn't find it. In the end I went to a local used equipment dealer and bought a junker for parts.

I knew it went quite a distance, but all the way to New York is pretty astounding. Just put it in a "special place" in case you need it in the future.

I knew it went quite a distance, but all the way to New York is pretty astounding. Just put it in a "special place" in case you need it in the future.