- Joined

- Nov 8, 2011

- Messages

- 1,678

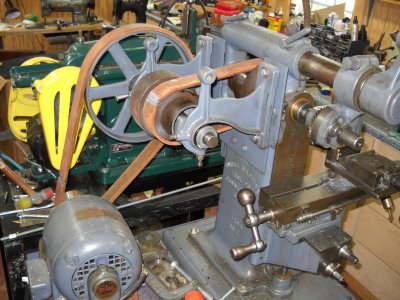

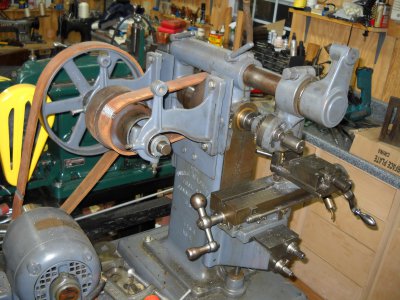

Remember I said my vertical head attachment had locked up, I was mistaken. I took the head off to try out some tooling Benny had brought over to me for the horizontal function. While we were trying it out it locked up again. The issue was the 2 locking rings that take the end play out of the spindle. One was loose from the other and backed off tightening against the bronze/brass bushing. I adjusted it and tightened them together/against each other and all seems fine. I need to fix my vice now. I tried out the slotting cutter he brought me on both steel & aluminum, we hogged some pretty good cuts for such a little machine. It worked really well on the aluminum.

I need to get some better belting & figure out my spindle speeds with the pulleys that are on it and the motor RPM, I think it will smooth out really nice. I think once I have it dialed in perfectly I will put it on the market as I really need a full size machine & don't have room or the $$$ for both.

I need to get some better belting & figure out my spindle speeds with the pulleys that are on it and the motor RPM, I think it will smooth out really nice. I think once I have it dialed in perfectly I will put it on the market as I really need a full size machine & don't have room or the $$$ for both.