- Joined

- Mar 17, 2018

- Messages

- 1,400

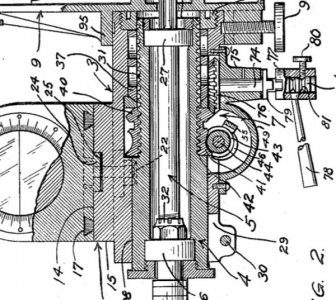

I should imagine that the manufacturer made some provision for disconnecting the quill gearbox in order to facilitate setup much like the worm may be disengaged on a rotary table so that it may be freely rotated.

This feature is not always obvious.

I strongly agree .