Good Day all,

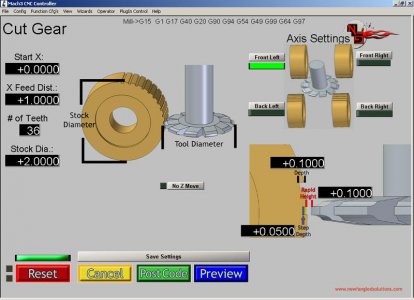

Can someone please point me in the right direction as to writing G code for a gear . I have a 4th axes on my cnc mill . I am using Mach3 and the A axes is set up for it. So where would I start if I wanted to make gear say of 26 teeth 50mm long with a depth of 3.5 mm . Any help appreciated .

thanks

charles

Can someone please point me in the right direction as to writing G code for a gear . I have a 4th axes on my cnc mill . I am using Mach3 and the A axes is set up for it. So where would I start if I wanted to make gear say of 26 teeth 50mm long with a depth of 3.5 mm . Any help appreciated .

thanks

charles