- Joined

- Mar 26, 2018

- Messages

- 8,397

I started this on another thread, this one seems more appropriate.

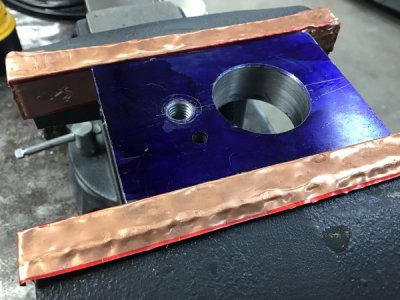

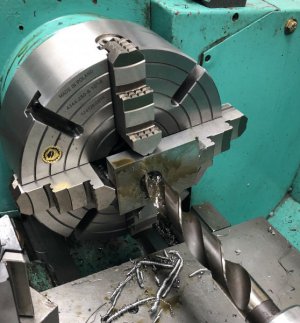

I’m in the process of fabricating a cam lock and plunger to replace the original broken/repaired/broken part.

This morning I finished milling the plate to size and bored the hole to 1.500”.

Next step, mark and center punch the plunger hole.

Then I need to layout the cut for the slitting saw.

The order of operations is getting interesting.

I’m in the process of fabricating a cam lock and plunger to replace the original broken/repaired/broken part.

This morning I finished milling the plate to size and bored the hole to 1.500”.

Next step, mark and center punch the plunger hole.

Then I need to layout the cut for the slitting saw.

The order of operations is getting interesting.

Attachments

-

44B10FA2-F952-407E-908D-C3FC0F6C7F73.jpeg68.2 KB · Views: 26

44B10FA2-F952-407E-908D-C3FC0F6C7F73.jpeg68.2 KB · Views: 26 -

80E72003-B65E-450C-A367-AA7A7017B240.jpeg61.7 KB · Views: 27

80E72003-B65E-450C-A367-AA7A7017B240.jpeg61.7 KB · Views: 27 -

EED286D3-B285-4FC4-90FB-23F994DAE9FF.jpeg76.3 KB · Views: 27

EED286D3-B285-4FC4-90FB-23F994DAE9FF.jpeg76.3 KB · Views: 27 -

0A27C420-664B-4A4A-AE24-7AB8793DCCF2.jpeg47.9 KB · Views: 26

0A27C420-664B-4A4A-AE24-7AB8793DCCF2.jpeg47.9 KB · Views: 26 -

21043F51-BE3A-41B4-BDCF-BC51D6B4A18A.jpeg58.2 KB · Views: 27

21043F51-BE3A-41B4-BDCF-BC51D6B4A18A.jpeg58.2 KB · Views: 27 -

81CA0026-6D12-429F-9F2D-F0D4D3B4F060.jpeg74.7 KB · Views: 28

81CA0026-6D12-429F-9F2D-F0D4D3B4F060.jpeg74.7 KB · Views: 28 -

948967B0-38FC-49F5-99BC-807EEEE3F221.jpeg56.1 KB · Views: 29

948967B0-38FC-49F5-99BC-807EEEE3F221.jpeg56.1 KB · Views: 29 -

1930EA77-52A9-445E-9E49-87FC545F658C.jpeg59.9 KB · Views: 29

1930EA77-52A9-445E-9E49-87FC545F658C.jpeg59.9 KB · Views: 29