- Joined

- Mar 2, 2018

- Messages

- 232

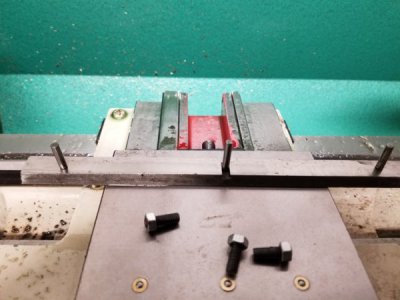

I just finished doing a 6-bolt compound mod on my g0602 using the ready-made kit on offer from Belfanti Machine Works. The installation went very well, but reassembly hasn't gone as smoothly. After I put everything back together, I have to keep the gib screws extremely loose to allow the cross-slide to travel. They are much too loose, and any gains I got from the 6-bolt mod are canceled by the new slop in the cross-slide.

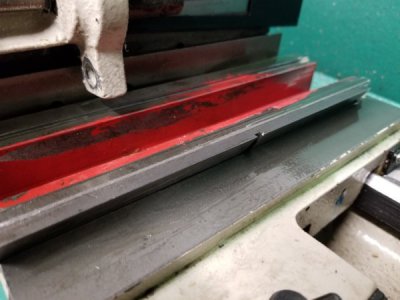

I already went back to the drawing board once, to make sure I had the gib installed correctly. I did not, in fact. I missed getting the adjuster pin into the slot the first time. now that I have corrected that, getting the cross-slide back on is much easier, but I still have the binding issue. I don't see how I could have bent the gib, but maybe I did. It also has a rough patch one one end. I originally chalked this up to the condensation-related corrosion problem I've been fighting, but it later hit me that I'm probably looking at scale that wasn't ground off, and the gib probably has a big low spot right there.

Maybe there's some trick to this I'm missing, like tightening the gib screws in a certain order or something. Maybe I need to read up on scraping my ways. I'm really not sure where to go from here, and I thought I'd ask for advice from more experienced folks. This is the first metal lathe I've ever handled, and I haven't had it very long.

I already went back to the drawing board once, to make sure I had the gib installed correctly. I did not, in fact. I missed getting the adjuster pin into the slot the first time. now that I have corrected that, getting the cross-slide back on is much easier, but I still have the binding issue. I don't see how I could have bent the gib, but maybe I did. It also has a rough patch one one end. I originally chalked this up to the condensation-related corrosion problem I've been fighting, but it later hit me that I'm probably looking at scale that wasn't ground off, and the gib probably has a big low spot right there.

Maybe there's some trick to this I'm missing, like tightening the gib screws in a certain order or something. Maybe I need to read up on scraping my ways. I'm really not sure where to go from here, and I thought I'd ask for advice from more experienced folks. This is the first metal lathe I've ever handled, and I haven't had it very long.