- Joined

- Feb 2, 2016

- Messages

- 17

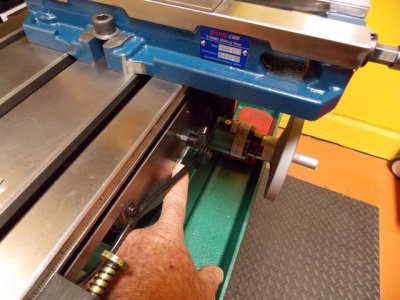

First off I have to say that I really like my new Grizzly G0755 milling machine. To complement the mill, I purchased the Grizzly T10063 4" premium milling vice. With the new vice installed, the vice overhangs the table, which is normal for these types of vices. The problem I encountered was centering the cutting bit to the vice jaws. Using the center T slot to attach the vice would put the vice to far back (towards the user) which makes the saddle overhang the base. Using the first T slot, the vice overhangs to much, and is unbalanced, but the cutting bit can be centered OK. Using the forward T slot, the vice cant be centered without maximum saddle overhanging the base. What I'm after is to have the vice jaws centered and the saddle under full support on the base. What I did to compromise was to drill two 1/2" X 13 tpi holes into the table, between the T slots to mount the vice. I also have s swivel base vice that I use. This vice, in order to get it to center as above, I have to off set the swivel base mounting holes using two T slots

First off I have to say that I really like my new Grizzly G0755 milling machine. To complement the mill, I purchased the Grizzly T10063 4" premium milling vice. With the new vice installed, the vice overhangs the table, which is normal for these types of vices. The problem I encountered was centering the cutting bit to the vice jaws. Using the center T slot to attach the vice would put the vice to far back (towards the user) which makes the saddle overhang the base. Using the first T slot, the vice overhangs to much, and is unbalanced, but the cutting bit can be centered OK. Using the forward T slot, the vice cant be centered without maximum saddle overhanging the base. What I'm after is to have the vice jaws centered and the saddle under full support on the base. What I did to compromise was to drill two 1/2" X 13 tpi holes into the table, between the T slots to mount the vice. I also have s swivel base vice that I use. This vice, in order to get it to center as above, I have to off set the swivel base mounting holes using two T slots

Last edited: