To start, if you have searched on this forum for the Grizzly G0773, as I have, the most notable comment, & I paraphrase, "Lotta money for a little machine." Yet, it doesn't fit neatly into the benchtop group because it is kinda big for that group - yet the mill portion is really small for that group as well. So, no-one admits to having 1 or all have stayed clear. Given parts replacement can take 6 months, it may well be that few are sold.

I knew I needed a mill when I went shopping. Didn't need much in size as my interest was in making parts for bass guitars. Now I am new to milling, not that I hadn't admired the trade - cause from a young age I have & do admire the trade. I just don't know the trade. But, I ventured that for a little more money, I could have my small mill & a lathe all in 1.

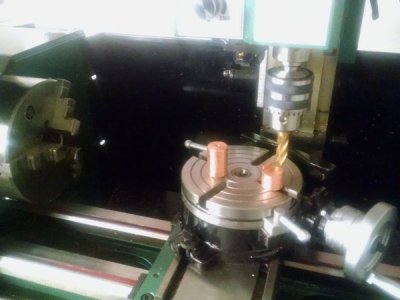

Here it is loading onto my bench.

Now back in the early 20th Century it was understood that tools of the trade here in the USA needed fine tuning once you bought them. Hand Planes are a fine example of this truth. I had no illusions of my Grizzly being good to go. First challenge was getting the compound on the cross slide to rotate 360 degrees. This is best solved by making a plug that allows the T nuts for the cross slide to glide across the access hole for the T nuts.

More to come & by all means, if you have this or similar please share your improvements!

I knew I needed a mill when I went shopping. Didn't need much in size as my interest was in making parts for bass guitars. Now I am new to milling, not that I hadn't admired the trade - cause from a young age I have & do admire the trade. I just don't know the trade. But, I ventured that for a little more money, I could have my small mill & a lathe all in 1.

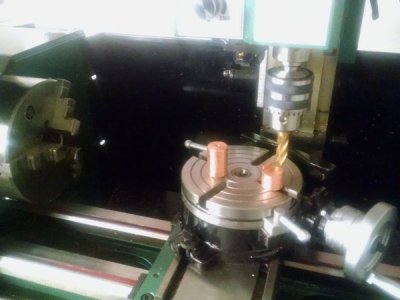

Here it is loading onto my bench.

Now back in the early 20th Century it was understood that tools of the trade here in the USA needed fine tuning once you bought them. Hand Planes are a fine example of this truth. I had no illusions of my Grizzly being good to go. First challenge was getting the compound on the cross slide to rotate 360 degrees. This is best solved by making a plug that allows the T nuts for the cross slide to glide across the access hole for the T nuts.

More to come & by all means, if you have this or similar please share your improvements!