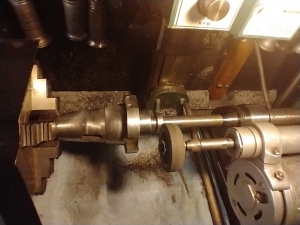

For my next trick, the 80 total graduations on the crossfeed dial have to go. A single revolution does equal 0.010" so it's high time to regraduate this to the proper 100 graduations. Step 1 is finding a 1/8" set of number stamps in a likable font.

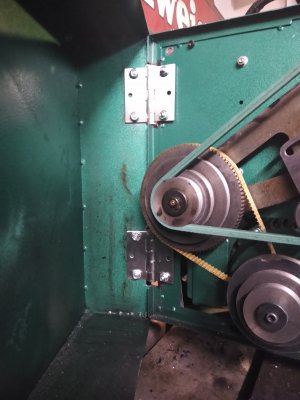

And, Yes, the trick will be doing this successfully on the 1st try. I'll be using a dividing head if I can work out the setup. It's all new to me (Pretty sure I'll be saying that for years to come).

And, Yes, the trick will be doing this successfully on the 1st try. I'll be using a dividing head if I can work out the setup. It's all new to me (Pretty sure I'll be saying that for years to come).

Last edited: