So i need to cut some M28 x 1mm threads for an adaptor i am making.

Long story short they cut close but its not right. I checked it with my gauges and its closer to 27 TPI than 1.0 mm....

not perfect 27 TPI but its a lot closer than 1mm

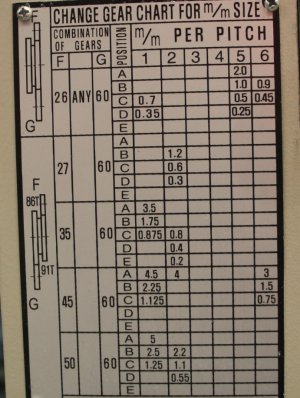

I change over to a 26 top gear and have the 60 on the bottom. it says any middle gear combo so I'm good there.

I have it set at position B - 5.... but no dice....

Threads looks great they just are not spaced properly.

Anyone have any suggestions? Why can't i cut a 1mm thread? I cut 1.25 and 1.5 all the time and never have an issue.

Thanks in advance

Long story short they cut close but its not right. I checked it with my gauges and its closer to 27 TPI than 1.0 mm....

not perfect 27 TPI but its a lot closer than 1mm

I change over to a 26 top gear and have the 60 on the bottom. it says any middle gear combo so I'm good there.

I have it set at position B - 5.... but no dice....

Threads looks great they just are not spaced properly.

Anyone have any suggestions? Why can't i cut a 1mm thread? I cut 1.25 and 1.5 all the time and never have an issue.

Thanks in advance

Last edited: