- Joined

- May 22, 2019

- Messages

- 89

From 270 to 1400 rpm my machine shakes like there is something out of balance or round somewhere in the drivetrain or spindle. It can be seen with the naked eye if you look at say the tip of the live center while mounted and while machine running. The spindle seems to be good as checked with my dti so, I don’t think it’s that. It does it no matter if back gears are engaged or not but I do see some wobble in the lowest gear and it binds a bit when I rotate by hand in one spot so I know it’s out of round but like I said it does this no matter if gears are engaged or not.

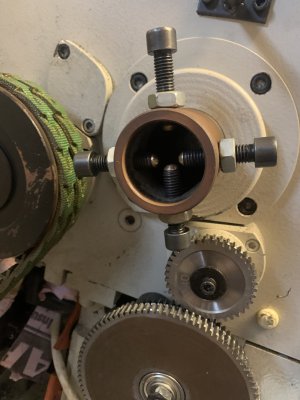

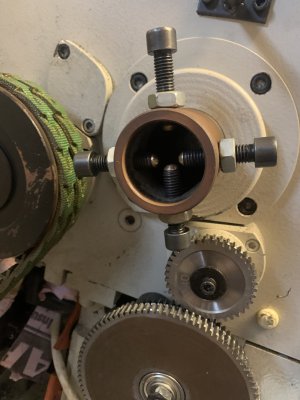

So my fix was to use the threaded holes on the rear of shaft for spider studs,I believe they are called, and started by moving one out,locking it down and them turning on the machine and adjusted as seemed fit. Picture below is showing what I did but, not sure if this could cause problems down the road? I don’t see why it would since it cleared up a noticeable amount of the shaking but I would like some experienced guys to comment on it please? Also when I’m auto feeding in the x and Watching the hand wheel it like pauses for a split second but it’s randomn and not at the same spot in rotation. What could cause that? Thanks

So my fix was to use the threaded holes on the rear of shaft for spider studs,I believe they are called, and started by moving one out,locking it down and them turning on the machine and adjusted as seemed fit. Picture below is showing what I did but, not sure if this could cause problems down the road? I don’t see why it would since it cleared up a noticeable amount of the shaking but I would like some experienced guys to comment on it please? Also when I’m auto feeding in the x and Watching the hand wheel it like pauses for a split second but it’s randomn and not at the same spot in rotation. What could cause that? Thanks