- Joined

- May 26, 2015

- Messages

- 745

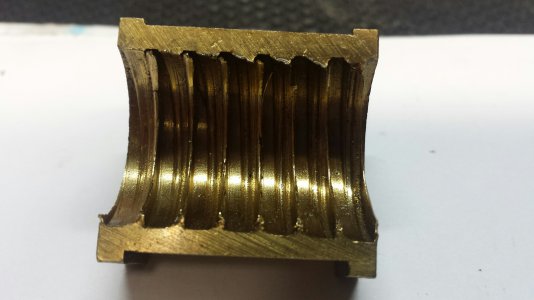

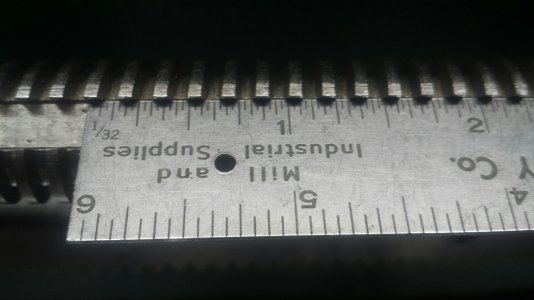

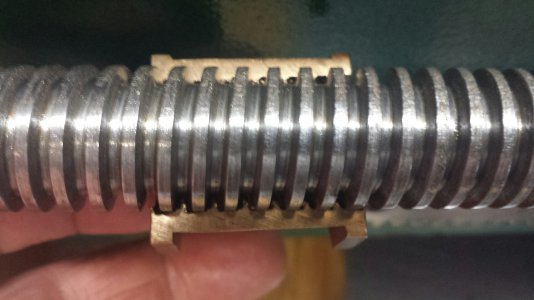

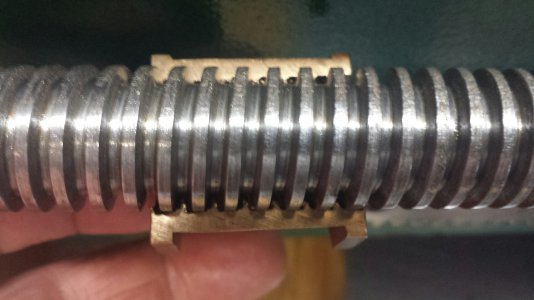

I have the Grizzly G9729 17x31 and would like to try my hand at making my own half nut. At $75 a pop I need a spare or two. I've already replaced it once and they wear fast even when frequent cleaning and lubing. Question "is" does anyone know what the Acme type/TPI/pitch is for the lead screw. A tap is around $100 and want to order the correct tap. American Standard/ Metric etc.

I called Grizzly Tech Support and they didn't know. The guy said he would try and find out but was not too optimistic. Thanks

I called Grizzly Tech Support and they didn't know. The guy said he would try and find out but was not too optimistic. Thanks

Last edited: