- Joined

- Oct 13, 2014

- Messages

- 6,523

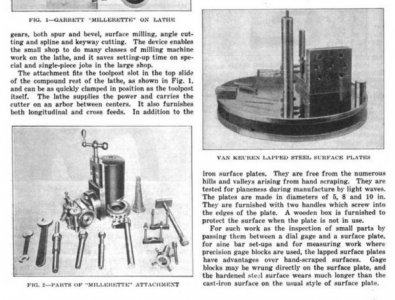

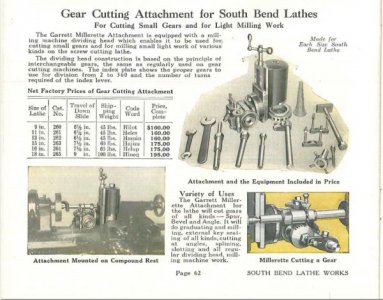

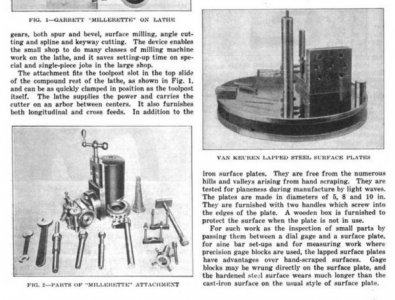

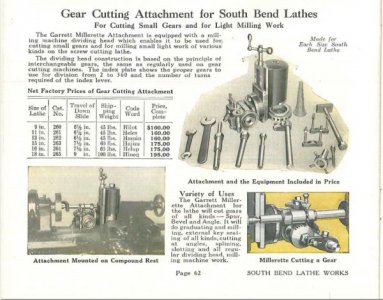

This rare dividing attachment came along with the South Bend Lathe I just bought,I searched the internet and came up with not much information on it other than it is a milling/dividing attachment and was listed in the South Bend catalogs in the 1930's (I haven't checked other decades yet). It looks to be unused or barely used. The lathe is circa 1935 so I assume it's the same age... I was wondering if anyone else has ever seen or used one of these before and knows anything about it? I know an instruction book exists, though not readily available. However, the use seems pretty straightforward so it ultimately it may not be necessary... Any info would be appreciated.