- Joined

- Sep 29, 2017

- Messages

- 2,251

Hi guys.

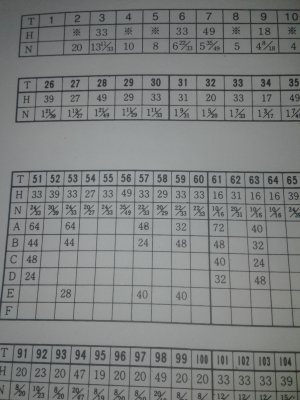

I don't know where I went wrong,but I need some help. I made a set of change gears for my big lathe and I actually posted another thread about this,but I wanted to post a new thread for all to see who maybe able to see where I went wrong. Please bear with me if this is a bit long.

It is four gears and here is the configuration.

Now three gears worked out as planned, but the 57 tooth gear blank finnished with 60 teeth. NOW HOW THE HECK DID THAT HAPPEN. When I put all four gears next to each other, they still mesh but somehow the "57" teeth,that is now 60 teeth,just will not fit when on the machine.

It looks like somehow the OD of the 57 tooth gear is to big,but I can't see where I went wrong. So I will give the information I think you need to HELP me see if I made a calculation mistake.

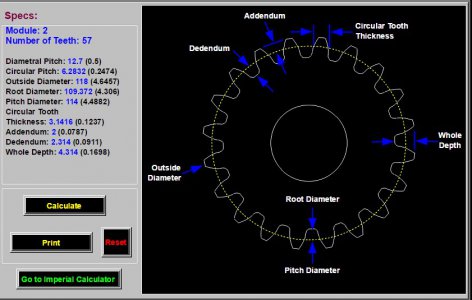

Here is the info for the gear Module=2.

N=57

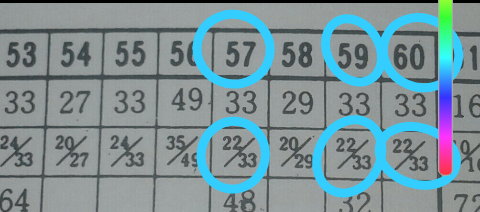

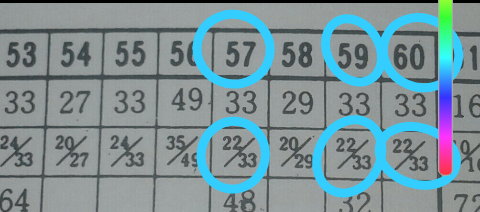

With this you are supposed to be able to get the OD for the blank and from there all the other information needed to make the gear.....right? And that gave me 118mm. Could the centre distance between the gear and Idler gear influence the OD of both gears? And with the given chart I have wich came with my Vertex dividing head I must use a 33 hole plate and move every 22 holes to make a 57 tooth gear,but what I found very interesting looking for my mistake today is this.

What I found interesting is that to make these three divisions, for all three you need to move 22 holes on a 33 hole plate and 60 is one of them. Is that coincidence or what?

PLEASE HELP ME!!!!!!!

If any other information is needed, please let me know and I will post it tomorrow, because I don't have it with me right now.

Thanks in advance.

Michael.

I don't know where I went wrong,but I need some help. I made a set of change gears for my big lathe and I actually posted another thread about this,but I wanted to post a new thread for all to see who maybe able to see where I went wrong. Please bear with me if this is a bit long.

It is four gears and here is the configuration.

Now three gears worked out as planned, but the 57 tooth gear blank finnished with 60 teeth. NOW HOW THE HECK DID THAT HAPPEN. When I put all four gears next to each other, they still mesh but somehow the "57" teeth,that is now 60 teeth,just will not fit when on the machine.

It looks like somehow the OD of the 57 tooth gear is to big,but I can't see where I went wrong. So I will give the information I think you need to HELP me see if I made a calculation mistake.

Here is the info for the gear Module=2.

N=57

With this you are supposed to be able to get the OD for the blank and from there all the other information needed to make the gear.....right? And that gave me 118mm. Could the centre distance between the gear and Idler gear influence the OD of both gears? And with the given chart I have wich came with my Vertex dividing head I must use a 33 hole plate and move every 22 holes to make a 57 tooth gear,but what I found very interesting looking for my mistake today is this.

What I found interesting is that to make these three divisions, for all three you need to move 22 holes on a 33 hole plate and 60 is one of them. Is that coincidence or what?

PLEASE HELP ME!!!!!!!

If any other information is needed, please let me know and I will post it tomorrow, because I don't have it with me right now.

Thanks in advance.

Michael.