- Joined

- Sep 29, 2017

- Messages

- 2,251

Good question.3 times 19?

Good question.3 times 19?

I do.Do you have a 19 hole plate?

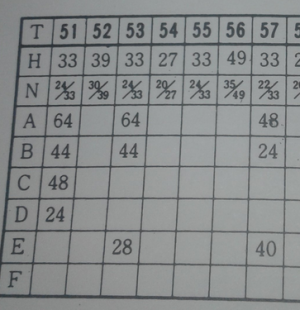

So do I have it correct if I make one rotation plus one hole on the the 19 hole plate to make a 57 tooth gear?

Do you have a 19 hole plate?

Making a plate up with the DRO will work well. For one offs 3D printing is quite good enough if you've got that capability. Differential indexing is pretty fun, though.

So do I have it correct if I make one rotation plus one hole on the the 19 hole plate to make a 57 tooth gear?

I must make a 57 hole plate using my DRO. What do you guys think?