Hi all, I just signed up here and thought I'd post a brief introduction and describe what I'm working on.

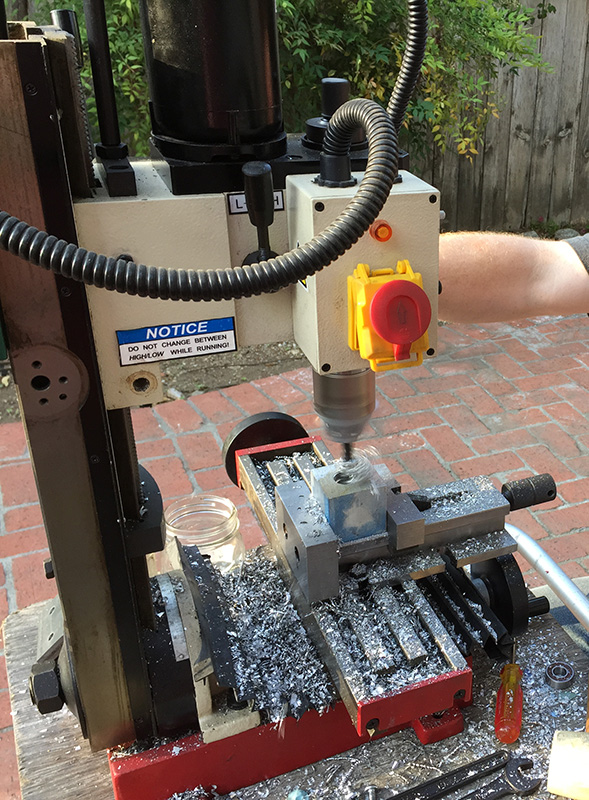

About 10 years ago I bought a Grizzly G0516, which I gather is basically an SX2 mill and C6 lathe joined at the hip. I separated them and mounted the mill on one of Little Machine Shop's table assemblies. Then over the years I got into a few small projects here and there, but always had time constraints related to my job and other factors. Next month, however, I'll be retiring, and with a lot more time available plan to spend more getting back into machining.

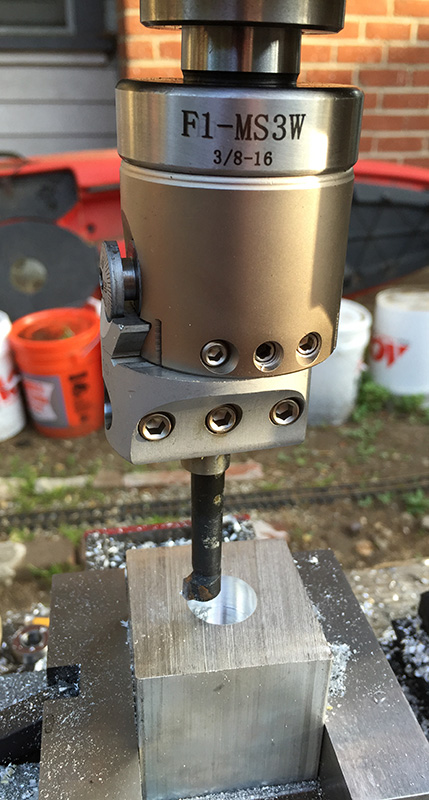

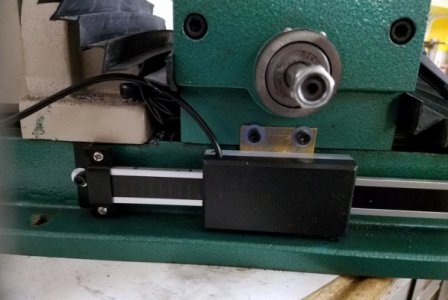

One of the projects I never quite got wrapped up as of yet was getting digital readout installed on the mill and lathe. Sometime back I bought three iGaging digital readouts (two 12" 35-712, one 6" 35-706) with the idea of mounting them on the mill. It appeared as though the main question would be to determine the mount points and then drill/tap holes and screw them on. For the X-axis, it appeared to me that I'd need to mill a piece of metal as an adapter. The only other issue of note is that I was concerned about swarf falling onto the DRO bar and causing electrical issues. So I was also thinking about installing flexible clear plastic sheets over the X and Y DRO's to cut down on swarf contamination. But, the DRO's have been sitting in a box and this is a project that hasn't quite gotten done. If anyone has any suggestions, maybe a link to an example of someone who did a nice job with these iGaging DRO's on a mill of this class, I'd be very interested to look at it.

Eventually I may be thinking about moving up to a larger mill. At times the G0516 has seemed undersized or underpowered for some of the things we've wanted to do. Getting a mill with integrated DRO would be a huge plus -- I'd much rather go that way than have to install an add-on kit. On the other hand, I'm not really looking at getting into CNC. So if anyone has suggestions on options in moving up from an SX2-size mill that have integrated DRO, I'd be very interested.

Looking forward to learning a lot here.

About 10 years ago I bought a Grizzly G0516, which I gather is basically an SX2 mill and C6 lathe joined at the hip. I separated them and mounted the mill on one of Little Machine Shop's table assemblies. Then over the years I got into a few small projects here and there, but always had time constraints related to my job and other factors. Next month, however, I'll be retiring, and with a lot more time available plan to spend more getting back into machining.

One of the projects I never quite got wrapped up as of yet was getting digital readout installed on the mill and lathe. Sometime back I bought three iGaging digital readouts (two 12" 35-712, one 6" 35-706) with the idea of mounting them on the mill. It appeared as though the main question would be to determine the mount points and then drill/tap holes and screw them on. For the X-axis, it appeared to me that I'd need to mill a piece of metal as an adapter. The only other issue of note is that I was concerned about swarf falling onto the DRO bar and causing electrical issues. So I was also thinking about installing flexible clear plastic sheets over the X and Y DRO's to cut down on swarf contamination. But, the DRO's have been sitting in a box and this is a project that hasn't quite gotten done. If anyone has any suggestions, maybe a link to an example of someone who did a nice job with these iGaging DRO's on a mill of this class, I'd be very interested to look at it.

Eventually I may be thinking about moving up to a larger mill. At times the G0516 has seemed undersized or underpowered for some of the things we've wanted to do. Getting a mill with integrated DRO would be a huge plus -- I'd much rather go that way than have to install an add-on kit. On the other hand, I'm not really looking at getting into CNC. So if anyone has suggestions on options in moving up from an SX2-size mill that have integrated DRO, I'd be very interested.

Looking forward to learning a lot here.

Last edited: