- Joined

- Dec 31, 2013

- Messages

- 327

I've been using my SB 10K for awhile now with a 120v, split-phase motor. I'm at the point now that I would like to get reverse working for some metric threading but I've been completely stonewalled in having the motor switch directions correctly. This is a popular search topic, but I have yet to find the exact same motor/switch combination that I'm using. Before I waste another day in the shop, I thought I would try here for some help.

Here's the motor:

http://www.grainger.com/product/DAYTON-GP-Mtr-4K913?s_pp=false&=

And a pic of the label:

And a pic of the wiring terminals:

From the factory, it's pretty easy to reverse the motor, just swap the black and red wires.

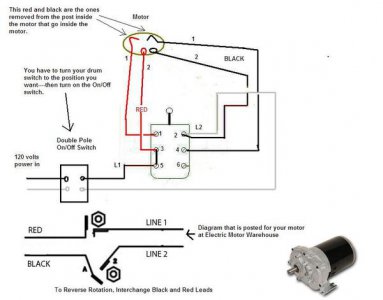

My lathe has a Cutler-Hammer drum switch. I could take a picture of it, but it will be very hard to decipher, so here's the schematic I used to wire it up.

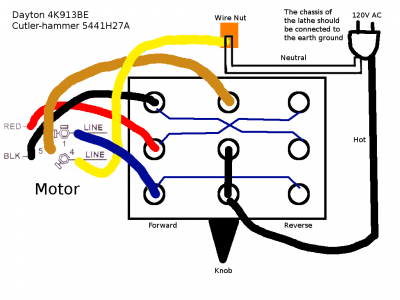

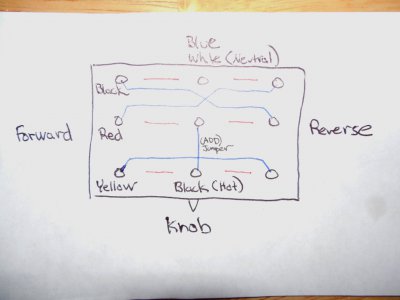

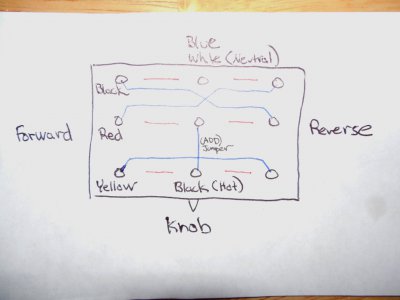

Each circle in the diagram is a screw. The blue lines are factory-installed jumper wires, except for the one I added in the middle. The red lines are the poles that are connected when the switch is activated, the left ones to the middle screws when forward is selected, the right ones to the middle when reverse is selected. Of course, in the middle none of the poles are connected (off). The black and white wires are 120v from the wall plug, the blue and yellow go to the main motor winding (screw lugs 1 & 4 in the motor pic above) and the red and black go to the start winding (red and black wires).

The neutral and blue wires are connected together and the black (hot) wire is switched, like a house light switch, so the main motor windings are connected the same for forward and reverse. The top two poles switch the red and black wire polarities.

When I tried the diagram as above, the motor worked and switched directions perfectly, but unfortunately the centrifugal switch seemed to be out of the circuit so the start winding was always activated, which is a very bad thing! Luckily, I noticed the motor sounded strange and was able to disconnect it long before the magic smoke came out.

Using a flashlight to look behind the panel, it seems the centrifugal switch is behind terminal 5. So I guess I need to run another wire to terminal 5 for a 5 wire setup? Then what? The right-top switch terminals are empty... Hmmm. This is harder than it should be. I feel like I'm missing something obvious.

Here's the motor:

http://www.grainger.com/product/DAYTON-GP-Mtr-4K913?s_pp=false&=

And a pic of the label:

And a pic of the wiring terminals:

From the factory, it's pretty easy to reverse the motor, just swap the black and red wires.

My lathe has a Cutler-Hammer drum switch. I could take a picture of it, but it will be very hard to decipher, so here's the schematic I used to wire it up.

Each circle in the diagram is a screw. The blue lines are factory-installed jumper wires, except for the one I added in the middle. The red lines are the poles that are connected when the switch is activated, the left ones to the middle screws when forward is selected, the right ones to the middle when reverse is selected. Of course, in the middle none of the poles are connected (off). The black and white wires are 120v from the wall plug, the blue and yellow go to the main motor winding (screw lugs 1 & 4 in the motor pic above) and the red and black go to the start winding (red and black wires).

The neutral and blue wires are connected together and the black (hot) wire is switched, like a house light switch, so the main motor windings are connected the same for forward and reverse. The top two poles switch the red and black wire polarities.

When I tried the diagram as above, the motor worked and switched directions perfectly, but unfortunately the centrifugal switch seemed to be out of the circuit so the start winding was always activated, which is a very bad thing! Luckily, I noticed the motor sounded strange and was able to disconnect it long before the magic smoke came out.

Using a flashlight to look behind the panel, it seems the centrifugal switch is behind terminal 5. So I guess I need to run another wire to terminal 5 for a 5 wire setup? Then what? The right-top switch terminals are empty... Hmmm. This is harder than it should be. I feel like I'm missing something obvious.

Last edited: