- Joined

- Jun 12, 2018

- Messages

- 712

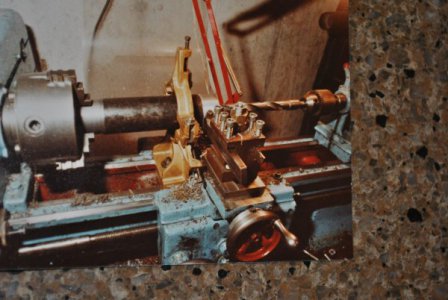

I've read a few times in this forum that some posters got rid of their compound slides on their mini lathes. Apparently, it makes it more ridgid for parting off.

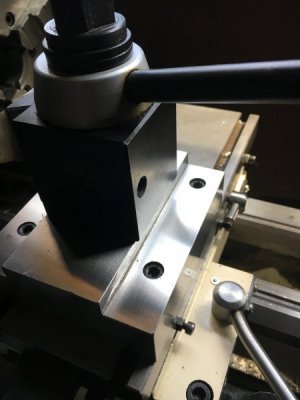

I'm thinking of doing the same thing. What are the pros and cons? So far, I haven't really had the need to use the compound and it's very hard to part off because of ridgidity problems on my 7x12. Do I just drill and tap the cross slide for the QCTP bolt?

I'm thinking of doing the same thing. What are the pros and cons? So far, I haven't really had the need to use the compound and it's very hard to part off because of ridgidity problems on my 7x12. Do I just drill and tap the cross slide for the QCTP bolt?