- Joined

- Nov 23, 2014

- Messages

- 2,606

Here’s another Erector set part string. This time it’s part number ‘DJ’ rear axle. This axle was used in the building of the iconic Gilbert White Truck model. The White Motor Company operated out of Cleveland, OH from 1900 – 1980. They produced (among other products) a popular general purpose truck chassis in the 1920’s that became dump trucks, fire trucks, flat beds, etc.

A.C. Gilbert had a sales staff that roamed the country trying to sell their wares to various department stores. A number of the salesmen got together and formed a company called Kelmet (from initials of the salesmen). Their primary product was a series of trucks modeled after the White truck chassis. Gilbert supported his employees endeavor by manufacturing the trucks for them. The business folded after a few years, so with dies in hand, Gilbert started including the White truck chassis parts in Erector sets starting in 1926. The model(s) continued in Gilbert Erector sets through 1962.

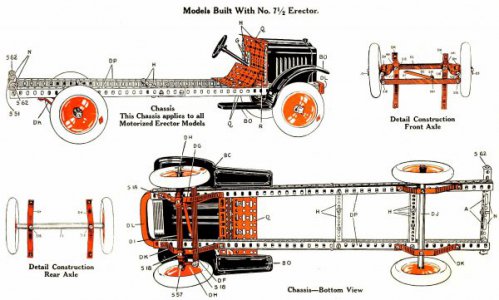

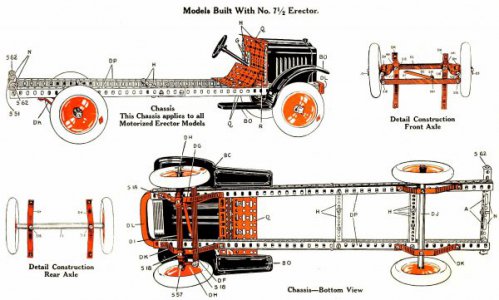

Instruction page from the 1927 manual showing the DJ axle and White truck chassis construction

The ‘DJ’ rear axle changed through the years. The ones reproduced here are circa 1927-28. These were lathe turned from 3/8” stock with 1” long ¼” diameter ends. Holes were cross-drilled for cotter pins to retain the wheels and 8-32 screws to attach the axle to simulated leaf springs.

Here's a rusty original DJ axle screwed to a pair of DK truck spirngs

As an aside, the early 1926 version did not have the cotter pin holes on the ends of the axle. Instead, the ends were threaded for 6-32 screws. The 1929 – 32 version was a straight length of ¼” rod with cotter pin holes at the ends. This later axle was attached to the leaf springs via a U-channel shaped piece of steel that was in turn screwed to the springs. The 1933 – 62 version was simplified further by attaching a standard 5/32” Erector set axle to the truck springs with a tear-drop shaped piece of sheet metal.

Really simply part here. I started by band sawing lengths of 303 stainless steel. Original parts were made from cold rolled steel and nickel plated. 303 looks very close to nickel plated CRS, so I go that route when possible to skip the plating process.

Chucked up the 3/8” stock in a collet and faced the end. Used a depth scale set to 1” and a carbide scribe to mark the end of the shoulder that would be turned to ¼” diameter. Once one end was turned, I pulled the part and measured the overall length with a 12” calipers. Overall length is 8 1/8”, so set the calipers there and scratched the length on the part. Chucked up the opposite end, faced to length and turned a second ¼” shoulder.

Moved to the mill where the 8-32 clearance holes and 5/64” cotter pin holes were spot drilled and drilled. Lastly, cleaned off the back side burrs with a Scotchbrite wheel.

Spot drilled the 4 cross holes

Through drill cotter pin holes

Through drill the 8-32 mounting screw holes

Banged out 4 reproductions

These aren’t a part I generally reproduce for sale since original parts are pretty plentiful. However, I’m in the process of putting together a 1927 No. 8 Erector set for sale on eBay and needed the part. Yeah, could have shopped for one on eBay, but as you can see, this one is pretty quick and dirty to make.

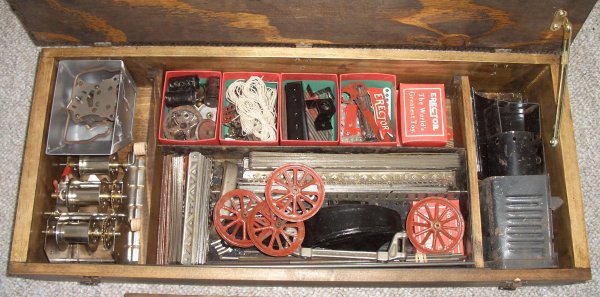

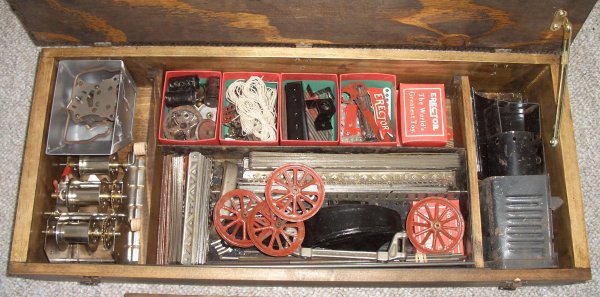

Photos are attached of a 1927 No. 8 set I sold a few years ago for $1200. The market is pretty soft right now, so will likely get closer to $800. Should help pay for my Bridgeport’s upcoming CNC upgrade!

1927 No. 8 set. Wooden box is 26" x 11" x 5" deep

A look under the top wooden tray

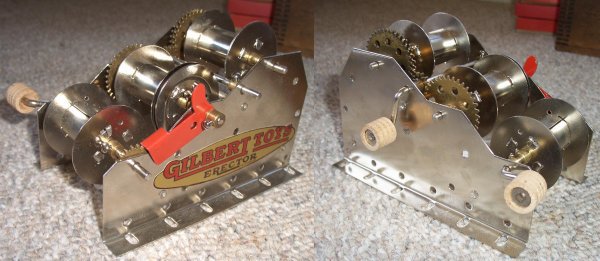

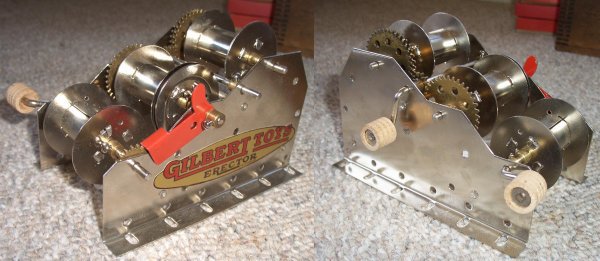

One of my reproduction part no. ED triple drum hoists

One of my reproduction part no. BP tip buckets

Chassis parts for building the White truck models

Thanks for looking,

Bruce

A.C. Gilbert had a sales staff that roamed the country trying to sell their wares to various department stores. A number of the salesmen got together and formed a company called Kelmet (from initials of the salesmen). Their primary product was a series of trucks modeled after the White truck chassis. Gilbert supported his employees endeavor by manufacturing the trucks for them. The business folded after a few years, so with dies in hand, Gilbert started including the White truck chassis parts in Erector sets starting in 1926. The model(s) continued in Gilbert Erector sets through 1962.

Instruction page from the 1927 manual showing the DJ axle and White truck chassis construction

The ‘DJ’ rear axle changed through the years. The ones reproduced here are circa 1927-28. These were lathe turned from 3/8” stock with 1” long ¼” diameter ends. Holes were cross-drilled for cotter pins to retain the wheels and 8-32 screws to attach the axle to simulated leaf springs.

Here's a rusty original DJ axle screwed to a pair of DK truck spirngs

As an aside, the early 1926 version did not have the cotter pin holes on the ends of the axle. Instead, the ends were threaded for 6-32 screws. The 1929 – 32 version was a straight length of ¼” rod with cotter pin holes at the ends. This later axle was attached to the leaf springs via a U-channel shaped piece of steel that was in turn screwed to the springs. The 1933 – 62 version was simplified further by attaching a standard 5/32” Erector set axle to the truck springs with a tear-drop shaped piece of sheet metal.

Really simply part here. I started by band sawing lengths of 303 stainless steel. Original parts were made from cold rolled steel and nickel plated. 303 looks very close to nickel plated CRS, so I go that route when possible to skip the plating process.

Chucked up the 3/8” stock in a collet and faced the end. Used a depth scale set to 1” and a carbide scribe to mark the end of the shoulder that would be turned to ¼” diameter. Once one end was turned, I pulled the part and measured the overall length with a 12” calipers. Overall length is 8 1/8”, so set the calipers there and scratched the length on the part. Chucked up the opposite end, faced to length and turned a second ¼” shoulder.

Moved to the mill where the 8-32 clearance holes and 5/64” cotter pin holes were spot drilled and drilled. Lastly, cleaned off the back side burrs with a Scotchbrite wheel.

Spot drilled the 4 cross holes

Through drill cotter pin holes

Through drill the 8-32 mounting screw holes

Banged out 4 reproductions

These aren’t a part I generally reproduce for sale since original parts are pretty plentiful. However, I’m in the process of putting together a 1927 No. 8 Erector set for sale on eBay and needed the part. Yeah, could have shopped for one on eBay, but as you can see, this one is pretty quick and dirty to make.

Photos are attached of a 1927 No. 8 set I sold a few years ago for $1200. The market is pretty soft right now, so will likely get closer to $800. Should help pay for my Bridgeport’s upcoming CNC upgrade!

1927 No. 8 set. Wooden box is 26" x 11" x 5" deep

A look under the top wooden tray

One of my reproduction part no. ED triple drum hoists

One of my reproduction part no. BP tip buckets

Chassis parts for building the White truck models

Thanks for looking,

Bruce