- Joined

- Nov 27, 2012

- Messages

- 7,852

To change belts on the Jet 2x42 the table has to be removed which is not a quick task. Some people have cut one "ear" of the table off which I don't want to do. The tables use multi position locking handles that you pull the handle out to move the handle in any position you want. So in order to get the table for the belt side off, you have turn to loosen the thread, pull the handle to move for more clearance, release & repeat until it finally comes off. Also need to remove a guide pin for the table bracket but I've manage to get around doing that by just manipulating the table at an angle to get it off.

On the left is the stock handle. In the middle is what I was using, same type of handle but with a hex head. I used this by pulling the handle up to the free postion then using a hex wrench to unscrew it. Then I learned there are safety multi position handles which is on the right. They work in reverse. The handle is free to move around, you push in to engage to tighten/loosen.

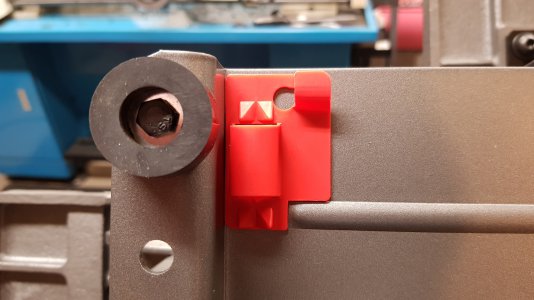

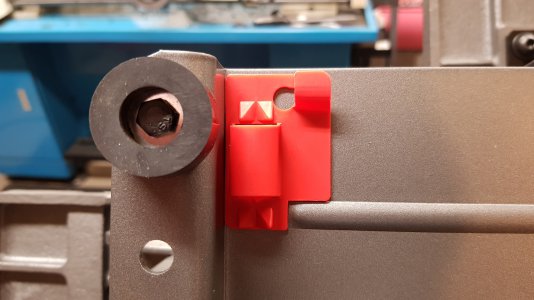

But when I got the safety handle I was sad to see it had a red cap like the stock handles. That's not going to work for me so I decided to try & modify it. Drilled the cap off, it was just pressed on.

Here's what it looked like inside.

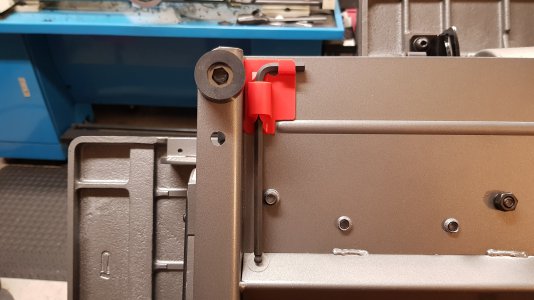

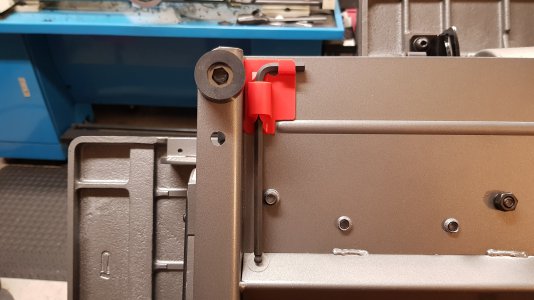

Cut the nub off, drilled & tapped for a M8 SHCS that fit the handle hole perfectly.

Now I can just use a hex wrench to unscrew the handle without having to pull up on the handle. Press in when I want to loosen/tighten to make adjustments for the table. This will do for now until I come up with a better mounting & adjustment design. The stock table mount is too finicky making adjustments which I don't like. I bought a dedicated hex wrench to keep with the sander.

Dammit, well now I wanted to make some type of mount for that hex wrench! I had thought about making some type of holder out delrin or something to mount to the base that probably would have taken me longer to make than it's worth. Then a simple idea came to mind, I'll just use the retail packaging for the hex wrench! Made a few cuts & mounted it to the bottom of the base, out of sight looking from the top, just reach under with one finger to slide it out. The bent ledge keeps it from flopping down. After I mounted it, I thought & laughed to myself, "that's kind of cheesy but that'll do just fine" (for now anyway).

Got me a bunch of belts & discs to play with, mostly ceramic for the belts but I picked up some zirconium, silicone carbide, & scotchbrite belts too. Happy to report that this belt sander has enough room to run the thick scotchbrite belts.

And finally, a member gave me a great idea, I purchased 2 extra discs to keep different grits on & just swap out when needed.

Any time I get a label printer in my hand I get a bit carried away. I put labels on the back of the discs & next to the the set screw so I can see them through the access hole for the set screw. Yeah yeah yeah, totally unnecessary but don't judge me!

Once again thanks for looking if you made it this far & sorry for boring you with these little things.

On the left is the stock handle. In the middle is what I was using, same type of handle but with a hex head. I used this by pulling the handle up to the free postion then using a hex wrench to unscrew it. Then I learned there are safety multi position handles which is on the right. They work in reverse. The handle is free to move around, you push in to engage to tighten/loosen.

But when I got the safety handle I was sad to see it had a red cap like the stock handles. That's not going to work for me so I decided to try & modify it. Drilled the cap off, it was just pressed on.

Here's what it looked like inside.

Cut the nub off, drilled & tapped for a M8 SHCS that fit the handle hole perfectly.

Now I can just use a hex wrench to unscrew the handle without having to pull up on the handle. Press in when I want to loosen/tighten to make adjustments for the table. This will do for now until I come up with a better mounting & adjustment design. The stock table mount is too finicky making adjustments which I don't like. I bought a dedicated hex wrench to keep with the sander.

Dammit, well now I wanted to make some type of mount for that hex wrench! I had thought about making some type of holder out delrin or something to mount to the base that probably would have taken me longer to make than it's worth. Then a simple idea came to mind, I'll just use the retail packaging for the hex wrench! Made a few cuts & mounted it to the bottom of the base, out of sight looking from the top, just reach under with one finger to slide it out. The bent ledge keeps it from flopping down. After I mounted it, I thought & laughed to myself, "that's kind of cheesy but that'll do just fine" (for now anyway).

Got me a bunch of belts & discs to play with, mostly ceramic for the belts but I picked up some zirconium, silicone carbide, & scotchbrite belts too. Happy to report that this belt sander has enough room to run the thick scotchbrite belts.

And finally, a member gave me a great idea, I purchased 2 extra discs to keep different grits on & just swap out when needed.

Any time I get a label printer in my hand I get a bit carried away. I put labels on the back of the discs & next to the the set screw so I can see them through the access hole for the set screw. Yeah yeah yeah, totally unnecessary but don't judge me!

Once again thanks for looking if you made it this far & sorry for boring you with these little things.