I done something stoopid. The kind of stupid that comes when you're sure you've done everything right, and reminds you that yep, nobody escapes without owning their very own part of stupidity.

So the project was fitting a blank D1-6 back plate to my small 4-jaw 8" chuck. I machined the back side for the spindle snout and achieved a great fit as shown by prussian blue. I mounted and adjusted the cam studs and installed the plate. Then I faced it, cut the register, blued it too, got my fit. Then onto the mill, where I used a tenths indicator in jig boring configuration to center the plate and drill and tap the hole pattern. Back on the lathe to torque on the chuck mounting bolts, everything fit snug and lovely. I mounted a scrapped part known to be true, and dialed it in. The Polish chuck was wobbling. I made sure the bolts were tight, they moved some, but man, this thing was out of whack.

I couldn't think of where I screwed up. I like to think I know what I'm doing in my own shop. It just didn't make sense, and ate at me for awhile. I put the chuck under the lathe and forgot about it for a few weeks. I pulled it out today to maybe try to re-examine it, even though I felt like it would be a dead end.

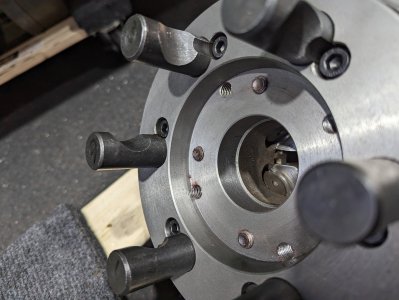

And then I saw this.

View attachment 448994

View attachment 448995