-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

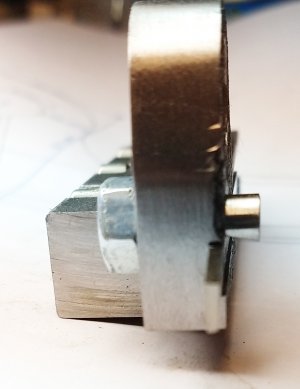

Gooseneck or spring-tool holder

- Thread starter petcnc

- Start date

- Joined

- Feb 1, 2015

- Messages

- 9,561

Another video showing the spring parting tool in action. 8 seconds in. https://www.hobby-machinist.com/threads/placa-4-castanhas-independent-four-jaws-chuck.80066/

- Joined

- Feb 1, 2015

- Messages

- 9,561

Thanks for sharing. A great explanation from Tom as to mechanics of the spring tool. If you think about it, this is exactly why using a parting tool upside down works so well.Here is a video on how these spring tool holders work.

Here is another video showing how it works when making a cut. Fast forward to about the 7 minute mark in the video.

- Joined

- Dec 29, 2012

- Messages

- 394

Ah ha! I'm reading this thread and not understanding how this works. Flex is the reason parting is a problem on smaller lathes. So you would think a tool holder that flexes would make matters worse.

The videos clarify that the key is the above the center line pivot point that causes the blade to kick out instead of dig in. And that makes total sense.

As others have mentioned, you have to wonder why they don't make these anymore.

The videos clarify that the key is the above the center line pivot point that causes the blade to kick out instead of dig in. And that makes total sense.

As others have mentioned, you have to wonder why they don't make these anymore.

If this really works I so need it because parting off for me always takes forever and/or end up in fireworks- even when I follow all the general advice. Since I have a threaded chuck running the lathe in reverse(for a rear mounted parting tool is not ideal.