- Joined

- Sep 24, 2019

- Messages

- 9

It's now dried off, lubricated and leveled.

Looks to have been manufactured in 1940. No power feeds.

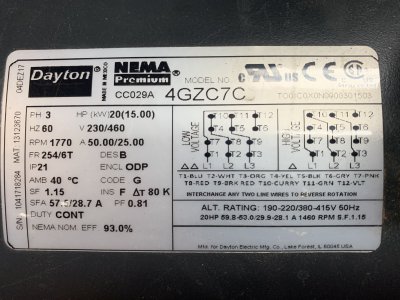

I only have single phase so first question is VFD or RPC. I don't have any other 3 phase machines so VFD seems like a good answer. But, I like the simplicity of an RPC. Cost isn't an issue, and I'm a computer/electrical engineer, so neither options seems particularly daunting. Any compelling reason(s) to go with one or the other?

Looks to have been manufactured in 1940. No power feeds.

I only have single phase so first question is VFD or RPC. I don't have any other 3 phase machines so VFD seems like a good answer. But, I like the simplicity of an RPC. Cost isn't an issue, and I'm a computer/electrical engineer, so neither options seems particularly daunting. Any compelling reason(s) to go with one or the other?