- Joined

- Aug 16, 2017

- Messages

- 150

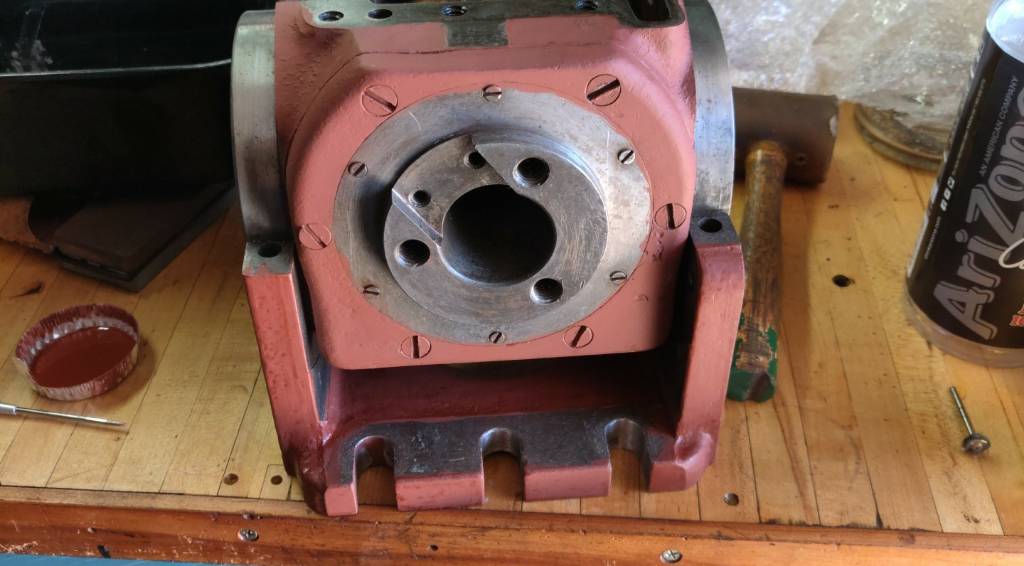

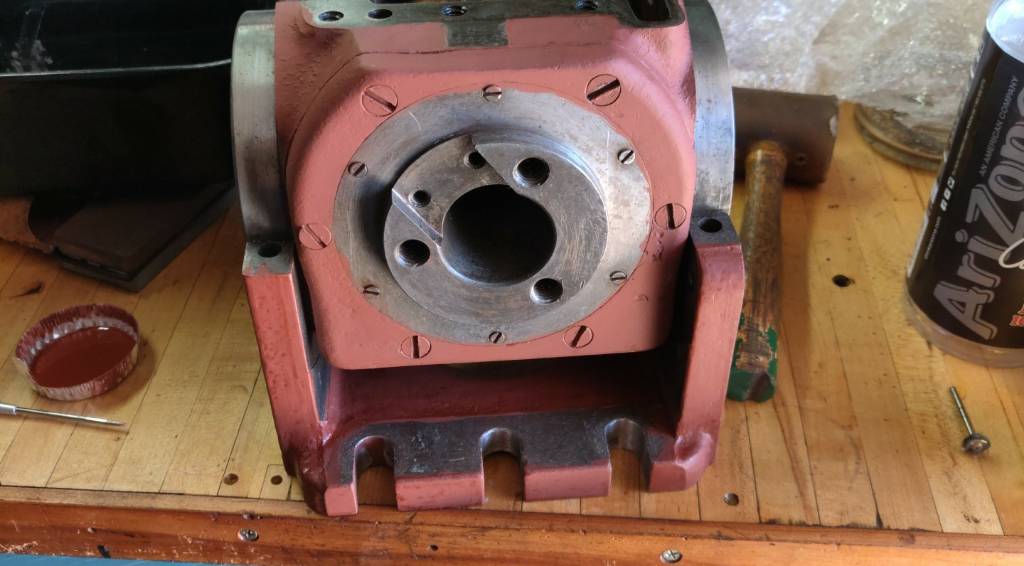

Long story short, this popped up on the Bay and the guy put it on CL so I could talk to him. Bought it last Wednesday and finally got it trucked to my house today. She was born in June 1943, so she just celebrated her 76th birthday. The guy I bought it from was horrified that I would think about selling my Bridgeport, but I still can't see why I need it considering what this beast is capable of. I also purchased the K&T dividing head that was originally on it, but no lead assembly to drive it. I'm already done stopping the paint that was slobbered on it and primed it for some industrial paint.

Enjoy!

Mark

Sent from my ONEPLUS A6013 using Tapatalk

Enjoy!

Mark

Sent from my ONEPLUS A6013 using Tapatalk