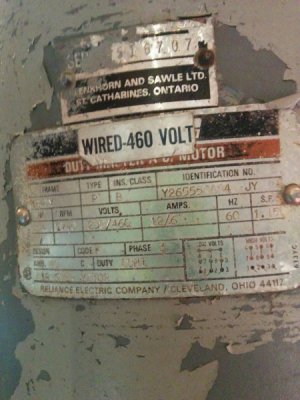

I hope this is in the right forum, I got my first machine recently its a Bridgeport series 2. It has a 4hp, 4j head I believe (correct me if I'm wrong I am just starting out!) The motor says it can br wired 230 or 460 and is currently wired for 460vac 3phase. Currently I only have 230 single phase, now I know about reconnecting the wires in the head to make it run on 230vac however I was told If I rewired for 220 I would have to change the heaters, fuses and re-wire the transformer for 230vac aswell is this correct? I plan on using either a vfd or rpc to sort out the 3 phase issue. Would it be cheaper to just get a transformer to go along with the vfd/rpc? I have photos if that helps!

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Got My First Machine!

- Thread starter Izzy

- Start date

- Joined

- Apr 4, 2016

- Messages

- 843

Yes, if the mill has a magnetic starter with heaters, you will have to change them and fuses for the appropriate current rating for 230V operation (the current draw will double when changing from 460V to 230V). I'm not sure what the function of the transformer is for your mill. If it only powers auxiliary 115V devices (axis drives, lights, etc.) or a 115V control circuit, you will have to change the line side tap from the 460V connections to 230V connections. The secondary taps will remain on the 115V connections.Also, if you use an RPC to run your mill, make sure not to connect the "generated" leg to the primary of the transformer.

Hope this helps

Ted

Hope this helps

Ted

Yes thank you that does help! How would I go abouts checking to see if it has a magnetic starter?

I believe the autofeeds get power from the machine itself maybe this is what it's for? I know I saw a big transformer in the control panel on the machine, I have pictures of that aswell if that helps?

How hard is it to change the heaters? Would i be better off just hiring an electrician or would it be cheaper to get a 220 to 460 volt transformer and leave the machine how it is?

Is there somewhere I could download manuals for this thing? It came with wiring diagrams but a manual would help alot!

I believe the autofeeds get power from the machine itself maybe this is what it's for? I know I saw a big transformer in the control panel on the machine, I have pictures of that aswell if that helps?

How hard is it to change the heaters? Would i be better off just hiring an electrician or would it be cheaper to get a 220 to 460 volt transformer and leave the machine how it is?

Is there somewhere I could download manuals for this thing? It came with wiring diagrams but a manual would help alot!

- Joined

- Jun 12, 2014

- Messages

- 4,806

An RPC could work with what you have, you would need to switch out the fuses and motor overload relay. The challenge is all the ancillary electronics. These might run off a specific tap from the transformer, if that is the case then you just need to switch the transformer input tap. A VFD would be a completely different picture, it is directly connected to the motor and you use low voltage switching to run the direction. Easier in some aspects of not needing contactors, overload relays, etc., but essentially you are gutting and doing a complete system build. Also looks like there is a quill power feed, as well as knee, X axis, and a coolant pump that is 3 phase. You would need to address all the systems voltages. I would check to see if there is a manual or schematic, it may give some guidance on what is required to switch voltages, I think doing that and going with an RPC would be a good route to consider first.

Manual is available for download, will check to see if there are any details on the electrical.

http://www.industrialmanuals.com/machine_manuals/pdfs/bridgeport seriess II standard milling machine installation,operation and maintenance.pdf

Manual is available for download, will check to see if there are any details on the electrical.

http://www.industrialmanuals.com/machine_manuals/pdfs/bridgeport seriess II standard milling machine installation,operation and maintenance.pdf

Last edited:

- Joined

- Apr 4, 2016

- Messages

- 843

IZ,

I am not familiar with your particular machine and without having a good electrical schematic for this machine, I would have to do a lot of speculating, which generally isn't a good idea with industrial controls. Based on the photo you posted of the electrical panel there are a few things I can determine. The three fuses in the upper right corner are on the main disconnect switch for the machine and those are the main fuses. These will have to be changed when you convert to 230V supply voltage. Directly below these fuses appear to be a reversing magnetic starter (or simple reversing contactor). If there are heaters, this is the component that will house them. They would also have to be changed. In the upper left corner are five more large fuses which I can only guess are a set of three for a three phase power source to possibly the table drive motor and a pair of two for possibly a single phase power source for maybe a coolant pump. There are several smaller fuses that are likely protecting various control circuits. In the lower center of the panel is what appears to be a solid state controller, very likely for the table drive motor/motors. Without a schematic, this is all guesswork and really of no value. It sounds like you are not familiar with industrial controls, so my first suggestion would be to get an electrician that is. You don't want to hire a general home type electrician as they generally wouldn't be familiar with industrial controls. Secondly, unless you want to tackle the job of completely updating that electrical panel and its electronic controls, I would not recommend using a VFD to power this machine. An RPC should work just fine, but as I said, you need a schematic so you can determine what changes (heaters, fuses, wiring connections, etc.) need to be made.

Ted

I am not familiar with your particular machine and without having a good electrical schematic for this machine, I would have to do a lot of speculating, which generally isn't a good idea with industrial controls. Based on the photo you posted of the electrical panel there are a few things I can determine. The three fuses in the upper right corner are on the main disconnect switch for the machine and those are the main fuses. These will have to be changed when you convert to 230V supply voltage. Directly below these fuses appear to be a reversing magnetic starter (or simple reversing contactor). If there are heaters, this is the component that will house them. They would also have to be changed. In the upper left corner are five more large fuses which I can only guess are a set of three for a three phase power source to possibly the table drive motor and a pair of two for possibly a single phase power source for maybe a coolant pump. There are several smaller fuses that are likely protecting various control circuits. In the lower center of the panel is what appears to be a solid state controller, very likely for the table drive motor/motors. Without a schematic, this is all guesswork and really of no value. It sounds like you are not familiar with industrial controls, so my first suggestion would be to get an electrician that is. You don't want to hire a general home type electrician as they generally wouldn't be familiar with industrial controls. Secondly, unless you want to tackle the job of completely updating that electrical panel and its electronic controls, I would not recommend using a VFD to power this machine. An RPC should work just fine, but as I said, you need a schematic so you can determine what changes (heaters, fuses, wiring connections, etc.) need to be made.

Ted

Thanks Ted, so your thinking I'd be better off leaving the machine how it is getting a 220-460VAC step up transformer and a RPC?

I did a little digging and I found out that the transformer inside the panel is infact for the axis motors as they run 90VDC. The machine came with the factory wiring diagram and and a chart for the heaters. Your absolutely right about me experience with industrial controls I'm a mechanic by trade though so I'm not completely cluess on electronic stuff and ohms law. Anything I can do myself I'll try anything more involved I'd be getting an electrician

I did a little digging and I found out that the transformer inside the panel is infact for the axis motors as they run 90VDC. The machine came with the factory wiring diagram and and a chart for the heaters. Your absolutely right about me experience with industrial controls I'm a mechanic by trade though so I'm not completely cluess on electronic stuff and ohms law. Anything I can do myself I'll try anything more involved I'd be getting an electrician

- Joined

- Apr 4, 2016

- Messages

- 843

IZ,

Using a step-up transformer is one option, but it's not the route I'd take if it were mine. (doesn't mean it's wrong, just not my preference) The old saying that "there ain't no free lunch" also applies to electricity. Using an RPC to power your machine induces electrical losses. Using an RPC and a step-up transformer will compound those losses. Also, those step-up transformers can be pricey. Making the necessary changes for the machine to operate on 230V shouldn't be that difficult, we just need some accurate, dependable information on that existing control panel, especially a good schematic. The last thing you want to do is let the smoke out of those "old school" electronics. Replacements probably aren't easy to come by.

I tried to zoom in on your photo of the control panel, but things just get too fuzzy for me to decipher any detail. Can you post a photo of the wiring diagram you have ? If it is clear enough to read accurately I should be able to help you with this.

Ted

Using a step-up transformer is one option, but it's not the route I'd take if it were mine. (doesn't mean it's wrong, just not my preference) The old saying that "there ain't no free lunch" also applies to electricity. Using an RPC to power your machine induces electrical losses. Using an RPC and a step-up transformer will compound those losses. Also, those step-up transformers can be pricey. Making the necessary changes for the machine to operate on 230V shouldn't be that difficult, we just need some accurate, dependable information on that existing control panel, especially a good schematic. The last thing you want to do is let the smoke out of those "old school" electronics. Replacements probably aren't easy to come by.

I tried to zoom in on your photo of the control panel, but things just get too fuzzy for me to decipher any detail. Can you post a photo of the wiring diagram you have ? If it is clear enough to read accurately I should be able to help you with this.

Ted

- Joined

- Feb 2, 2013

- Messages

- 3,620

I would not take the step up transformer route if it were my machine when a RPC is so simple to build

heaters and fuses are easy to change

the control transformer is easy to switch to 230v operation

there are newer components to replace any old school component that may be faulty

your transformer may have have some funny number/letter combinations

H1,H2,H3,H4 are all line connections

X1,X2,X3,X4 are secondary voltage

mostlikely your secondary voltage is 115vac, common for machine control voltage.

you can verify the coil voltage from any of the contactors, there is usually a legend plate that specifies voltage on the contactor itself

you'll retap the main motor for 230v operation

retap transformer

change your heaters to double capacity as you will pull twice the amps at 230vac

hook up RPC and make chips!

heaters and fuses are easy to change

the control transformer is easy to switch to 230v operation

there are newer components to replace any old school component that may be faulty

your transformer may have have some funny number/letter combinations

H1,H2,H3,H4 are all line connections

X1,X2,X3,X4 are secondary voltage

mostlikely your secondary voltage is 115vac, common for machine control voltage.

you can verify the coil voltage from any of the contactors, there is usually a legend plate that specifies voltage on the contactor itself

you'll retap the main motor for 230v operation

retap transformer

change your heaters to double capacity as you will pull twice the amps at 230vac

hook up RPC and make chips!

Last edited: